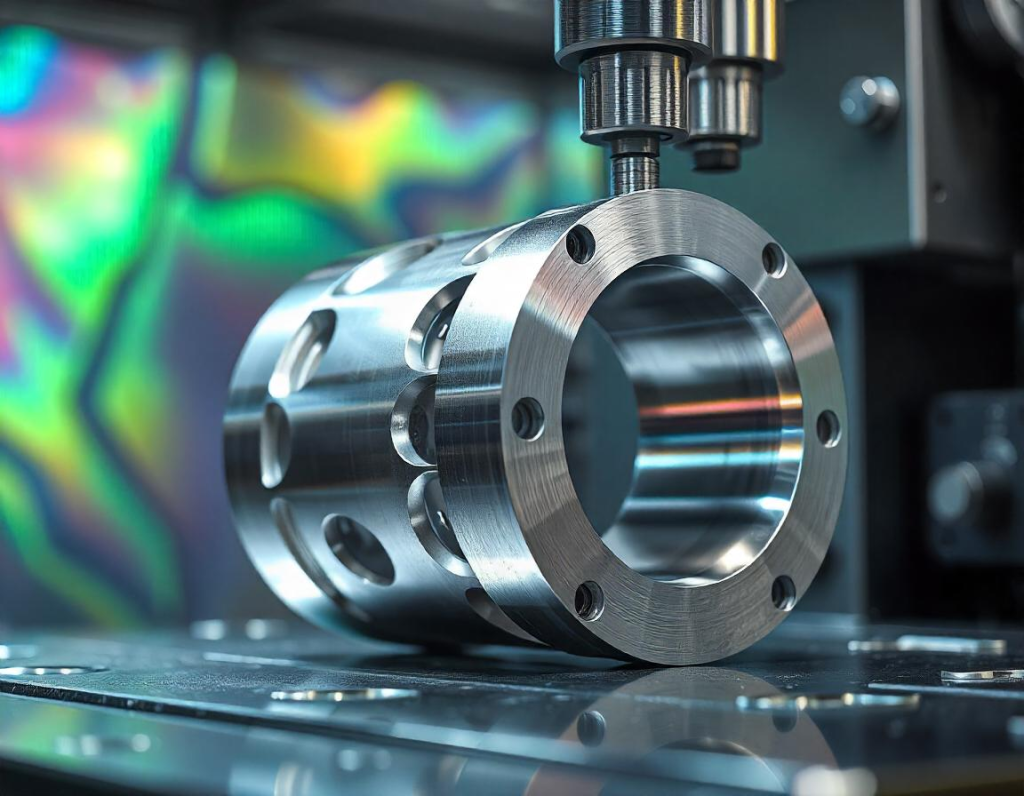

3-Axis CNC Machining

At V&S Engineering, we specialize in precision 3-axis machining, offering reliable and cost-effective solutions for a wide range of industries. This core machining technology enables the creation of intricate parts with exceptional accuracy, making it an essential tool in sectors such as aerospace, automotive, and medical.

3-Axis CNC Machining Services for Global Industries | V&S Engineering

At V&S Engineering, we provide high-precision 3 axis machining services for customers who require reliable, repeatable, and cost-effective machined components. Our 3-axis CNC milling capabilities are ideally suited for parts that demand tight tolerances, excellent surface finishes, and consistent quality without the complexity or cost of multi-axis machining.

From prototypes to full production runs, we machine components that perform exactly as intended in real-world applications for domestic and international clients.

3-Axis CNC Machining Services for Global Clients

V&S Engineering supports export-oriented manufacturing and international supply chains, delivering 3-axis CNC machined components for customers connected to USA, Canada, Germany, and Japan. Our machining processes emphasize process stability, dimensional consistency, and documentation, ensuring parts are suitable for global deployment and long-term use.

What Is 3-Axis CNC Machining?

3-axis CNC machining is a subtractive manufacturing process where the cutting tool moves along three linear axes — X, Y, and Z — to shape raw material into precise mechanical components. This machining method is commonly used for milling flat, prismatic, or moderately complex parts from a single primary orientation.

Despite the availability of 4-axis and 5-axis machining, 3-axis CNC machining remains one of the most widely used and dependable machining methods in modern manufacturing due to its accuracy, efficiency, and cost control.

When 3-Axis CNC Machining Is the Best Solution

3-axis machining is often the optimal choice when part geometry does not require simultaneous multi-side cutting or complex contours.

Typical applications include:

- Flat or prismatic components

- Parts with pockets, slots, profiles, and drilled holes

- Components that can be securely held in a vise or custom fixture

- Medium-to-high volume production runs

- Parts where cost efficiency and repeatability are critical

Choosing the correct machining method early in the process reduces lead times, lowers manufacturing costs, and improves part consistency—especially for international production programs.

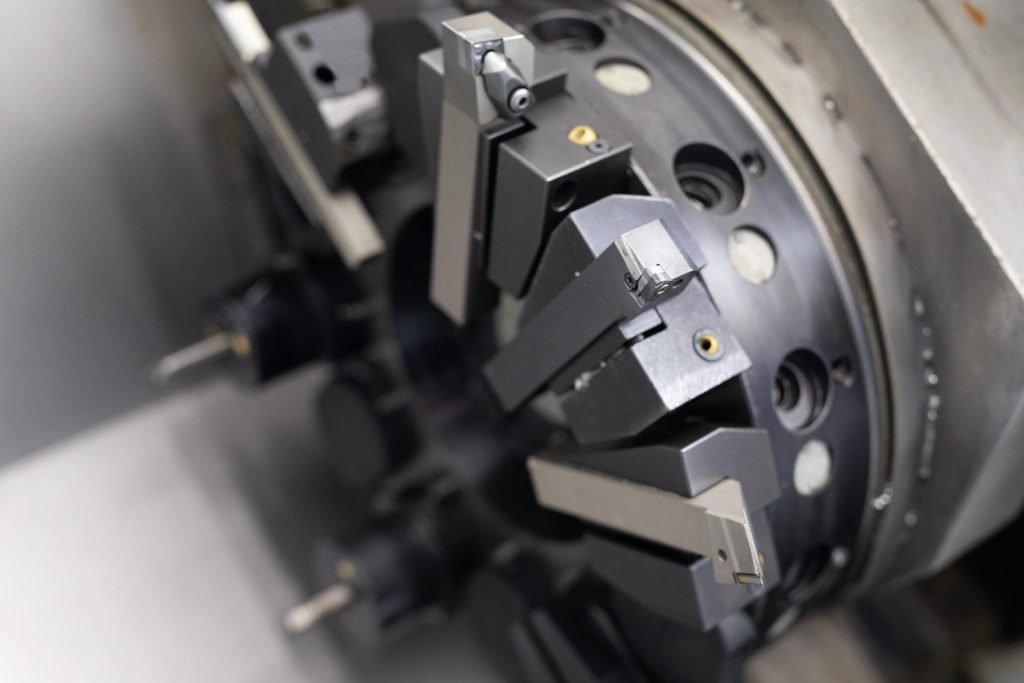

Our 3-Axis CNC Machining Capabilities

V&S Engineering operates advanced 3-axis CNC milling equipment supported by experienced machinists and proven internal processes. Our focus is not just on machining parts, but on controlling the entire machining process from setup to final inspection.

Our capabilities include:

- Precision CNC milling of simple to moderately complex geometries

- Tight-tolerance machining

- High-volume material removal

- Custom fixturing for repeatability and stability

- Consistent surface finishes

- Secondary machining operations as required

We design machining strategies that minimize setup changes, reduce dimensional stack-up, and ensure consistent results across every part—batch after batch.

Materials We Machine Using 3-Axis CNC Milling

Machining different materials requires more than changing tools—it requires understanding how each material behaves under cutting forces.

We regularly machine:

- Aluminum (various grades)

- Stainless steel

- Carbon steel

- Titanium

- Inconel®

- Additional specialty and exotic alloys

Each material is machined using optimized tooling, feeds, speeds, and inspection plans to maintain dimensional accuracy and surface integrity suitable for global industrial applications.

Aerospace & Defense 3-Axis CNC Machining

V&S Engineering supports aerospace and defense customers who require precision, consistency, and documented process control—often for international programs and export-controlled assemblies.

Our machining approach includes:

- Early identification of critical dimensions

- Defined machining and inspection sequences

- In-process inspections during production

- Calibrated inspection equipment

- Temperature-controlled inspection environment

These controls help ensure conformance to demanding specifications and reduce the risk of non-conforming parts.

3-Axis CNC Machining vs. 5-Axis Machining

While 5-axis machining allows for advanced geometries and simultaneous multi-face cutting, it is not always necessary.

3-axis CNC machining is often preferred when:

- Part geometry is straightforward

- Multi-axis motion does not add functional value

- Production efficiency and cost control are priorities

We evaluate each project based on functionality, tolerance requirements, and production volume—not on selling the most complex solution.

Quality Control & Inspection

Precision machining is only as good as the inspection process behind it.

Our quality control process includes:

- Multiple in-process inspections

- Final dimensional verification

- Routine calibration of inspection tools

- Controlled inspection environment for measurement accuracy

This disciplined inspection approach supports international customer expectations, ensuring components are suitable for global supply chains and overseas deployment.

Industries We Serve

Our 3-axis CNC machining services support a wide range of industries, including:

- Aerospace

- Defense

- Industrial equipment

- Manufacturing and automation

- Precision mechanical assemblies

Our components are commonly used in products supplied to the USA, Canada, Germany, and Japan, where consistency and repeatability are essential.

Why Choose V&S Engineering for 3-Axis CNC Machining?

Customers choose V&S Engineering because we provide:

- Precision-focused machining processes

- Strong material and application expertise

- Reliable quality control

- Clear and consistent communication

- On-time delivery

We work as a manufacturing partner, not just a machining supplier—supporting long-term production success.

Conclusion and Next Steps

As industries evolve, the demand for precision 3-axis machining continues to grow. Embracing this technology is essential for companies looking to enhance their manufacturing capabilities.

Contact us today to learn how V&S Engineering can meet your machining needs with precision and excellence.