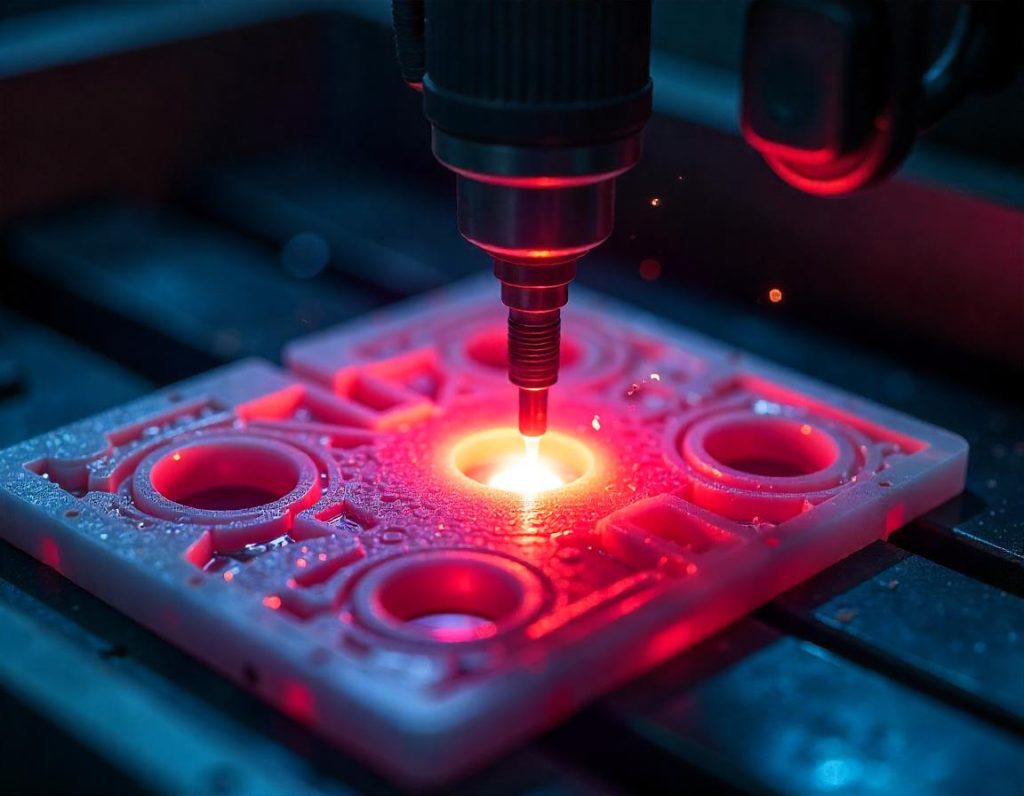

4-Axis CNC Machining

At V&S Engineering, we provide advanced 4 axis machining services that offer enhanced precision and flexibility for complex manufacturing needs. This technology allows for the production of intricate, multi-dimensional components with exceptional accuracy and efficiency. Our capabilities are designed to meet the high demands of industries such as aerospace, automotive, and medical, delivering reliable and high-quality solutions.

4-Axis CNC Machining Services

At V&S Engineering, we provide high-precision 4 axis machining services for customers who need more than basic 3-axis milling—but don’t want unnecessary complexity, cost, or risk.

Our 4-axis CNC machining capabilities are designed for parts that require indexed machining, tight positional accuracy, and repeatable multi-face features. From prototypes to production runs, we focus on machining parts that meet specifications the first time—and continue meeting them run after run.

What Is 4-Axis CNC Machining?

4-axis CNC machining expands on traditional 3-axis milling (X, Y, Z) by adding a rotary axis, commonly referred to as the A-axis. This axis allows the workpiece to rotate around a fixed axis, giving the cutting tool access to multiple sides of the part without manual repositioning.

In real manufacturing terms, this means:

- Fewer setups

- Better feature-to-feature alignment

- Reduced tolerance stack-up

- Improved repeatability

4-axis machining is especially valuable when part features are located around a diameter, across multiple faces, or require precise indexing at specific angles.

Why 4-Axis CNC Machining Matters in Real Production

Every time a part is removed from a fixture and re-clamped, an error is introduced. It might be small—but across tight tolerances, small errors become big problems.

4-axis machining solves this by:

- Keeping the part in a single controlled setup

- Using rotary indexing instead of manual repositioning

- Maintaining consistent datum relationships across features

For parts where true position, concentricity, or angular alignment matters, 4-axis machining dramatically reduces risk.

When 4-Axis CNC Machining Is the Right Choice

4-axis machining is often the best solution when 3-axis setups become inefficient or unreliable—but full 5-axis motion is unnecessary.

Common use cases include:

- Parts with features on multiple sides

- Components requiring precise hole patterns around a circumference

- Indexed pockets, slots, or flats at specific angles

- Cylindrical or prismatic parts with secondary features

- Components where setup reduction improves consistency

If your team is currently using multiple 3-axis setups to achieve the geometry, 4-axis machining often reduces cost, lead time, and scrap.

4-Axis vs. 3-Axis CNC Machining

While 3-axis machining is excellent for many parts, it has limitations when features span multiple faces.

3-Axis CNC Machining:

- Single-face access

- Requires multiple setups for multi-side features

- Higher risk of positional variation between setups

4-Axis CNC Machining:

- Rotary indexing enables multi-face machining

- Reduces re-clamping and manual alignment

- Improves feature-to-feature accuracy

In many cases, 4-axis machining delivers a measurable improvement in precision without increasing part cost.

4-Axis vs. 5-Axis CNC Machining

5-axis machining allows simultaneous movement across multiple axes and is ideal for highly complex contours. However, it is not always the most efficient or stable option.

4-Axis CNC machining is often preferred when:

- Geometry is indexed rather than continuous

- Multi-side access is required without compound angles

- Cost and programming simplicity are priorities

- Repeatability across production runs matters

At V&S Engineering, we recommend the machining method that best fits your part—not the most complex one.

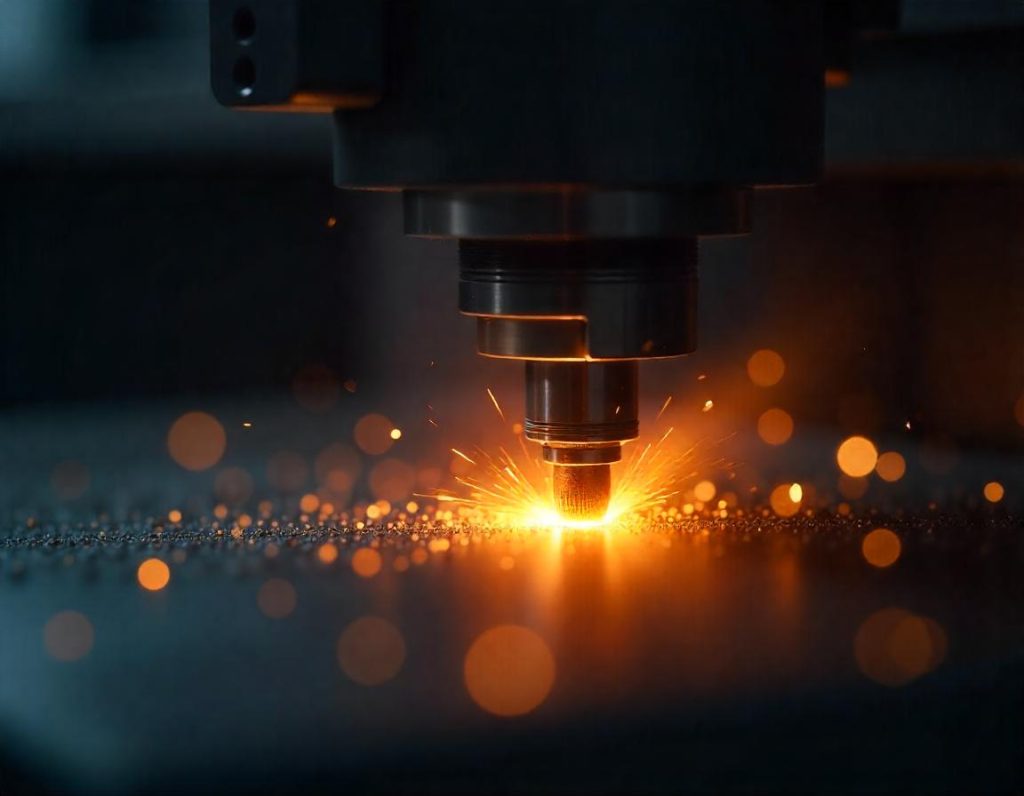

Our 4-Axis CNC Machining Capabilities

Our 4-axis machining services are built around process discipline, fixture stability, and dimensional control.

Capabilities include:

- Precision indexed milling

- Multi-face machining in a single setup

- Tight tolerance machining

- High-volume and repeat production

- Custom rotary fixturing

- Secondary machining operations

Each project begins with a detailed review of the print and model to determine the most stable and efficient machining strategy.

Materials We Machine Using 4-Axis CNC Equipment

Different materials behave very differently under rotary machining conditions. Our team accounts for this during programming, tooling selection, and inspection planning.

Materials include:

Aluminum

Stainless steel

Carbon steel

Titanium

Inconel®

Additional specialty and exotic alloys

Feeds, speeds, toolpaths, and inspection checkpoints are adjusted based on material behavior—not generalized assumptions.

Aerospace & Defense 4-Axis CNC Machining

Aerospace and defense components demand more than just dimensional accuracy—they require process control and repeatability.

Our approach includes:

- Identification of critical features and datums

- Controlled machining sequences

- In-process inspections

- Calibrated inspection tools

- Temperature-controlled inspection environment

This ensures that parts remain consistent across batches and production runs.

Quality Control & Inspection

Precision machining is meaningless without verification.

Our inspection process supports:

- In-process dimensional checks

- Final inspection before shipment

- Routine calibration of measuring equipment

- Controlled inspection conditions for accuracy

This approach minimizes scrap, rework, and downstream issues for our customers.

Industries We Serve with 4-Axis CNC Machining

Our 4-axis CNC machining services support customers across multiple industries, including:

- Aerospace

- Defense

- Industrial equipment

- Manufacturing automation

- Precision mechanical assemblies

Whether you need a one-off prototype or repeat production, our process remains consistent.

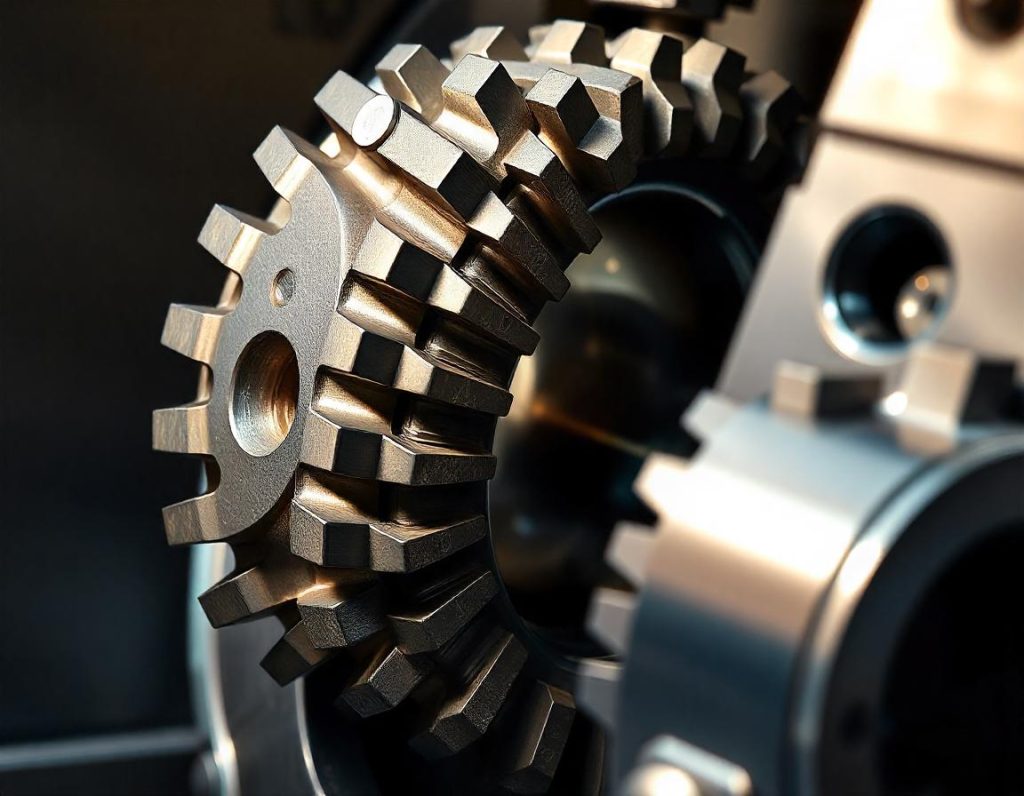

Why Choose V&S Engineering for 4-Axis CNC Machining?

Customers choose V&S Engineering because we provide:

- Process-driven machining, not guesswork

- Honest guidance on machining method selection

- Strong material and application knowledge

- Consistent quality control

- Clear communication from quote to delivery

We focus on long-term manufacturing partnerships, not just individual jobs.

Why Choose V&S Engineering

At V&S Engineering, we combine experience, cutting-edge technology, and a customer-centric approach to deliver top-notch machining services that align with your business goals.

Get in touch with us today to explore how our 4-axis machining solutions can enhance your manufacturing process.