5-Axis CNC Machining

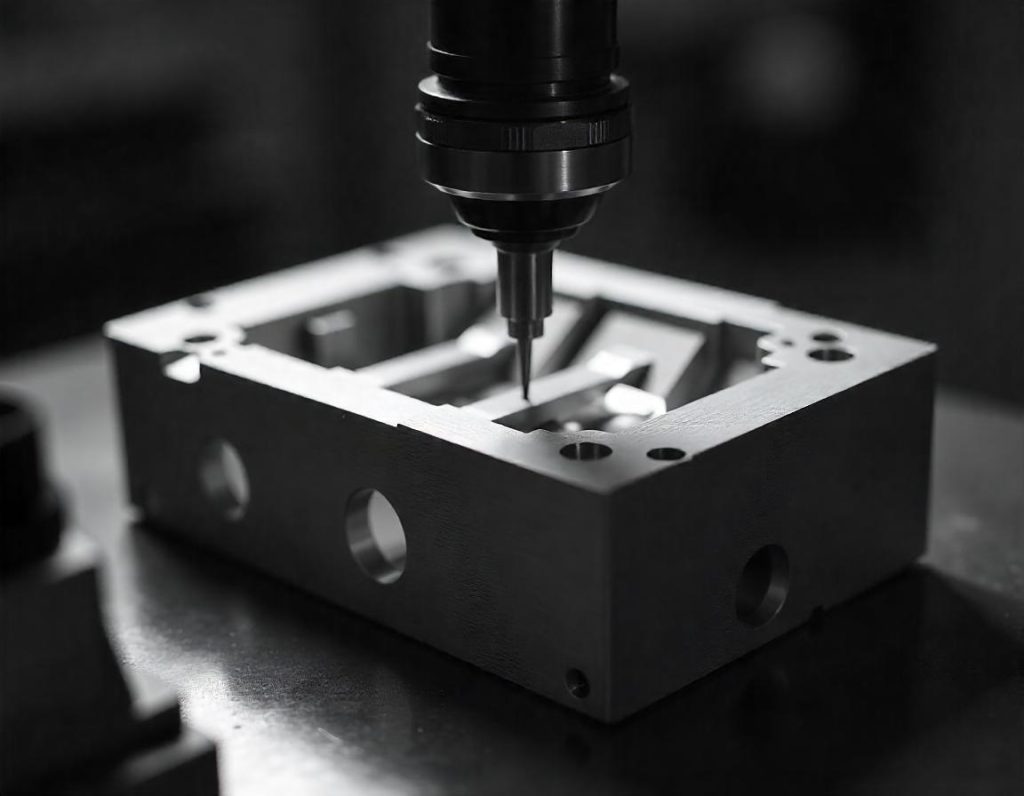

At V&S Engineering, we use 5-axis machining to make complex parts with high accuracy. This advanced technology allows tools to move in five directions, making it possible to create detailed shapes in one setup. Our services help industries like aerospace, automotive, and medical achieve their production goals with precision and efficiency.

5-Axis CNC Machining Services

At V&S Engineering, we provide advanced 5 axis machining services for precision components that require complex geometry, multi-face machining, and tight positional accuracy. Our 5-axis machining capabilities are ideal for parts that cannot be efficiently or accurately produced using traditional 3-axis or 4-axis machining methods.

Located in Huntington Beach, California, V&S Engineering supports customers across the United States with high-precision machining solutions for aerospace, defense, industrial, and engineered mechanical applications.

What Is 5-Axis CNC Machining?

5-axis CNC machining is a manufacturing process that allows cutting tools to move along five different axes simultaneously or positionally. In addition to the standard X, Y, and Z linear movements, 5-axis machines include two rotational axes, enabling the tool to approach the part from multiple angles during machining.

This expanded range of motion allows for:

- Machining multiple faces in a single setup

- Producing complex geometries with improved accuracy

- Reducing setup time and cumulative tolerance error

Achieving superior surface finishes on contoured features

When 5-Axis CNC Machining Is the Right Solution

5-axis machining is most effective when part geometry or tolerance requirements exceed the capabilities of simpler machining methods.

Common applications include:

- Components with features on multiple faces

- Parts with angled holes, pockets, or surfaces

- Complex contours and curved profiles

- Precision components requiring tight feature-to-feature relationships

- Parts where reducing setups improves consistency and lead time

By minimizing re-clamping and maintaining consistent datums, 5-axis machining improves part quality while streamlining production.

5-Axis CNC Machining Capabilities at V&S Engineering

V&S Engineering utilizes advanced 5-axis CNC machining processes supported by experienced machinists and disciplined production planning. Each project begins with a detailed review of part requirements to determine the most stable and efficient machining strategy.

Our capabilities include:

- Simultaneous and positional 5-axis machining

- Multi-face machining in a single setup

- Tight-tolerance machining

- Complex contoured surface machining

- Custom fixturing for stability and repeatability

- Prototype and production machining

Our approach focuses on machining accuracy, repeatability, and predictable results.

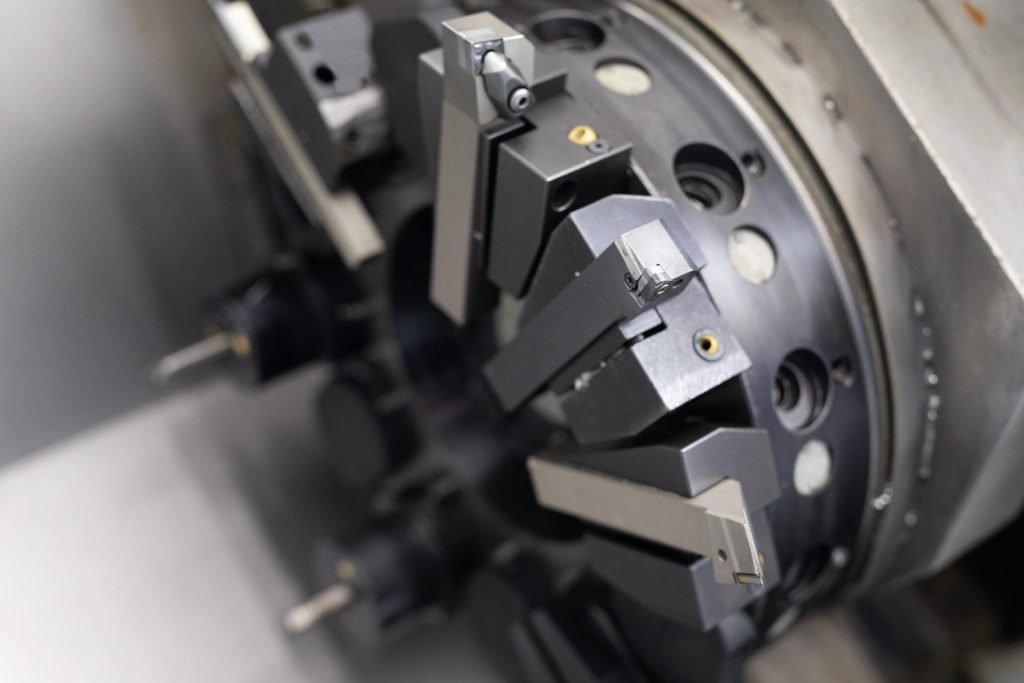

3-Axis vs 4-Axis vs 5-Axis CNC Machining

Choosing the correct machining method is critical for cost, quality, and delivery.

- 3-Axis Machining: Best for simple parts machined from one primary orientation

- 4-Axis Machining: Adds indexed rotation for multi-side access

- 5-Axis Machining: Enables complex geometry, compound angles, and reduced setups

V&S Engineering evaluates each part based on geometry, tolerance, and volume to determine the most effective machining solution.

Materials We Machine Using 5-Axis CNC Equipment

Our team has experience machining a wide range of materials using 5-axis CNC machining strategies optimized for each alloy.

Materials include:

- Aluminum

- Stainless steel

- Carbon steel

- Titanium

- Nickel-based alloys (including Inconel®)

- Additional specialty and exotic materials

Material-specific tooling, feeds, speeds, and inspection plans are applied to ensure dimensional accuracy and surface integrity.

Aerospace & Defense 5-Axis CNC Machining

V&S Engineering supports aerospace and defense manufacturing requirements by implementing controlled machining and inspection processes. Our team identifies critical dimensions early in production and maintains consistent quality throughout the machining process.

Quality measures include:

- In-process inspections

- Calibrated inspection equipment

- Temperature-controlled inspection environment

- Documented machining procedures

These practices support reliable part conformity for demanding applications.

Quality Control & Inspection

Precision 5-axis machining requires robust inspection processes to verify part conformance.

Our quality control approach includes:

- Dimensional inspections during production

- Final verification prior to shipment

- Routine calibration of measurement equipment

- Controlled inspection conditions

This ensures that complex components meet design specifications before delivery

Industries We Serve

Our 5-axis CNC machining services support a wide range of industries, including:

- Aerospace

- Defense

- Industrial equipment

- Manufacturing and automation

- Precision mechanical assemblies

Each project receives the same attention to process control and quality.

Future Trends in 5-Axis Machining

As technology evolves, future advancements in 5-axis machining will include:

- Automation: Streamlining operations and reducing human error through robotics and smart manufacturing.

- Real-Time Monitoring: Using IoT-enabled sensors to track machine performance and adjust processes on the fly.

- AI Integration: Enhancing efficiency with smarter processes and adaptive machining strategies to optimize productivity.

- Sustainable Practices: Developing eco-friendly machining solutions that minimize waste and energy consumption.

Why Choose V&S Engineering for 5-Axis CNC Machining?

Customers choose V&S Engineering because we provide:

- Advanced multi-axis machining capabilities

- Strong expertise in complex part manufacturing

- Reliable quality control processes

- Clear communication throughout production

- Consistent on-time delivery

We focus on long-term manufacturing partnerships built on trust and performance.