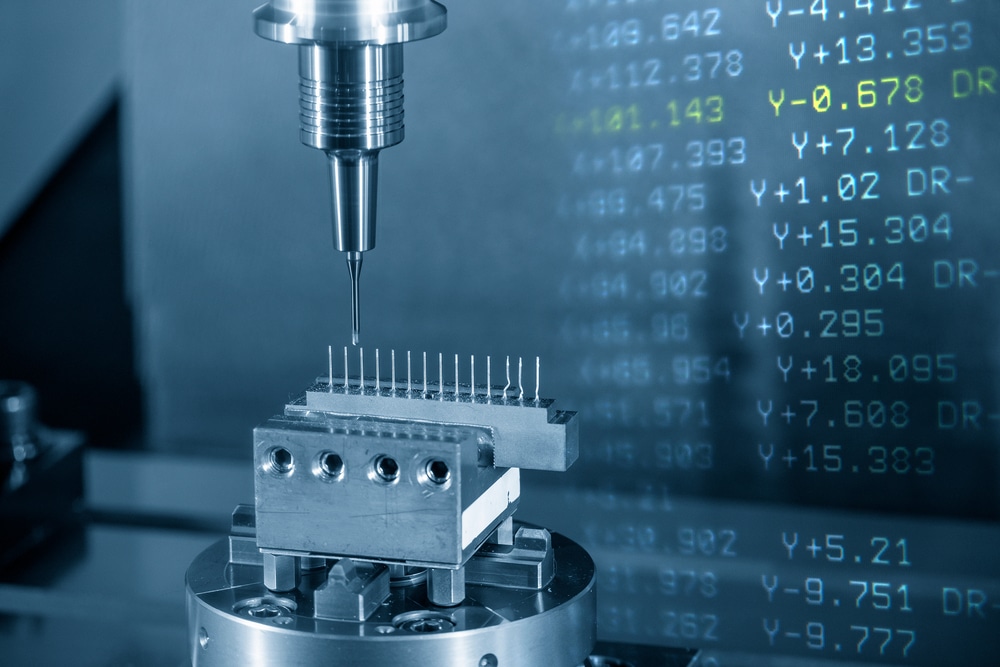

V&S Engineering – Trusted Precision Parts & Custom Fabrication Experts

At V&S Engineering, we’re more than just a CNC machine shop—we’re a family-founded company dedicated to delivering high-quality machining solutions through loyalty, craftsmanship, and real collaboration.

Who We Are

Crafting Quality, Honoring Legacy

V&S Engineering was born from a desire to honor family, elevate skilled work, and create a company where people—and quality—come first. We’re proud to be a woman-led business in a male-dominated industry, proving every day that integrity and initiative can move mountains.

From our CNC machines to our company culture, every detail matters. Whether you need a trusted partner for your production line or precision components built to spec, we’re here to help you build something that lasts.

What We Do

Precision CNC Machining Services

Why Clients Trust Us

Built On Values. Driven by Excellence.

Clients choose V&S Engineering because they want more than just parts—they want a team they can count on. Here’s what we stand for:

- Loyalty First: We build long-term relationships with every client and team member.

- We Take Initiative: We don’t wait to be told—if we see a problem, we solve it.

- Craftsmanship Counts: We hold ourselves to the highest standards of quality.

Our Story

From Vision to Reality

When we took over this business, we had a simple vision: to create something meaningful—not just for ourselves, but for our team, our clients, and our community.

Today, that vision is what drives us. Every part we craft, every team member we empower, and every challenge we solve is a step toward building a legacy that lasts. If you’re looking for a machine shop that puts people first, we’d love to connect.

Let’s Build Something Great Together

Have a project in mind? Let’s talk about how V&S Engineering can help bring it to life—with precision, partnership, and purpose.