CNC Milling Explained: How It Works and Why It Matters

Explore professional CNC milling services with precision machining, custom CNC milling solutions, and expert advice. Learn about CNC milling machines, 5-axis CNC, and CNC milling parts.

CNC (Computer Numerical Control) milling has become one of the most critical processes in modern manufacturing, enabling industries to produce high-quality, precise parts with exceptional efficiency. Whether you are a hobbyist looking for a desktop CNC milling machine or a business seeking large-scale custom CNC milling services, understanding CNC milling’s capabilities is crucial for selecting the right solution.

Having worked in CNC milling for years, I’ve seen firsthand how this technology continues to evolve, from simple 3-axis CNC milling machines to sophisticated 5-axis CNC milling machines. CNC milling services are at the heart of industries such as aerospace, automotive, medical, and electronics, where precision and repeatability are essential.

In this article, we’ll explore the different types of CNC milling machines, the benefits of CNC milling services, and how this process can help you achieve your manufacturing goals—whether you’re producing CNC milling parts, prototypes, or full-scale production runs.

What is CNC Milling?

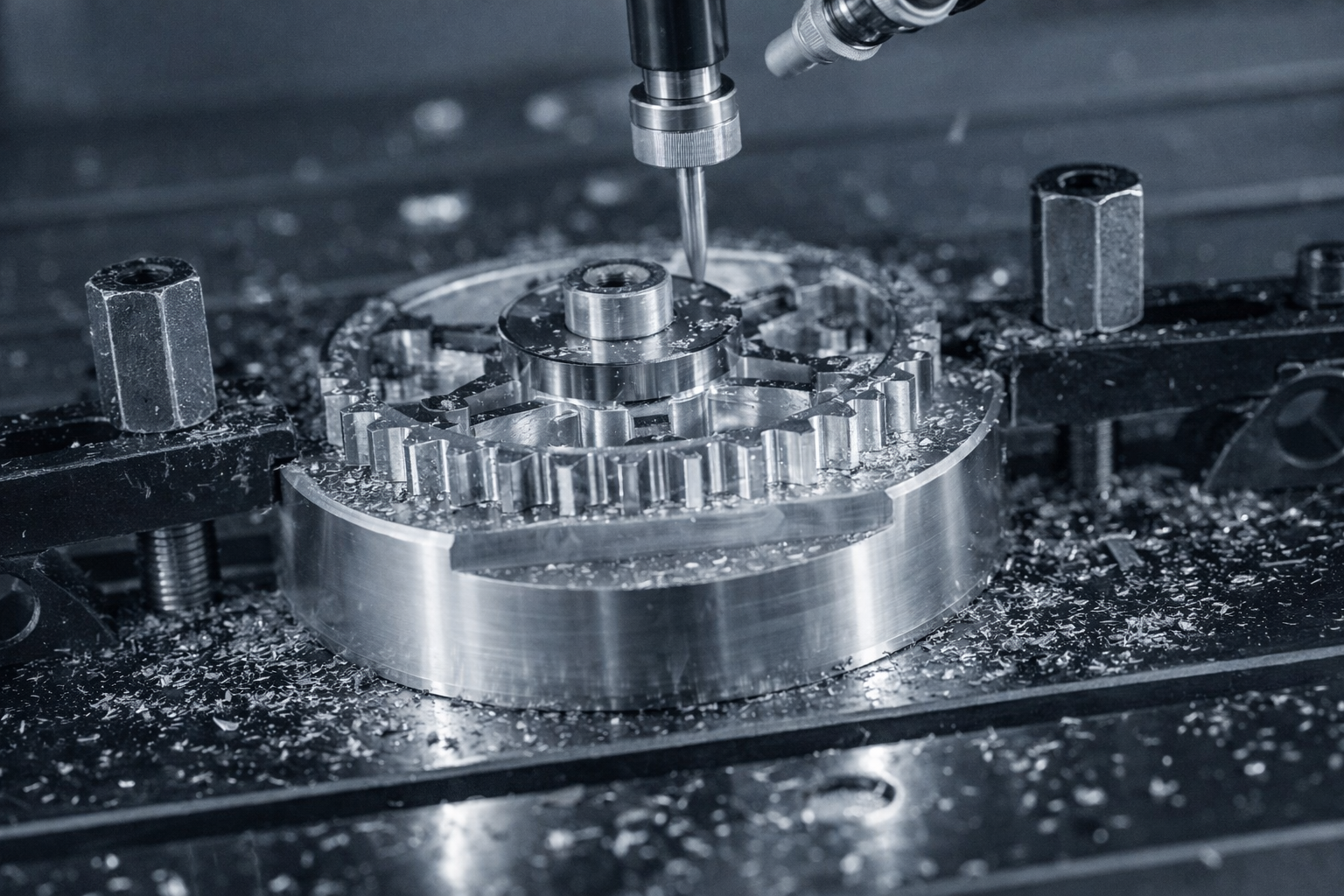

CNC Milling refers to a computer-controlled machining process where a rotating cutting tool is used to remove material from a workpiece. The machine follows instructions provided in the form of G-code, which directs the machine on how to move and cut the material in precise patterns along different axes. The result is a part or component with high precision and complex shapes.

CNC Milling Machines can vary greatly depending on their application. The most common machines in use are 3-axis CNC milling machines, which allow for cutting along three planes (X, Y, and Z). For more intricate parts, 5-axis CNC milling machines are commonly used. These machines can move along five axes simultaneously, allowing them to cut from multiple angles in one setup, making them ideal for complex geometries and reducing the time needed for reorienting the workpiece.

Some of the key advantages of CNC milling include:

- Precision: It offers incredibly tight tolerances, perfect for industries where accuracy is critical, like aerospace and medical device manufacturing.

- Efficiency: The automation of CNC milling allows for faster production runs with minimal human intervention.

- Versatility: CNC milling machines can work with a wide range of materials, including metals like aluminum, steel, and titanium, and plastics like acrylic and PVC.

The use of CNC milling machines has transformed how industries approach production, allowing for custom CNC milling solutions tailored to meet specific needs, whether it’s for prototyping or high-volume manufacturing.

Different Types of CNC Milling Machines

There are various types of CNC milling machines depending on your needs, whether it’s precision CNC milling or custom CNC milling services. Here’s a breakdown of the types of machines you may encounter:

- 3-Axis CNC Milling Machine

The most basic form, this machine moves in three directions (X, Y, and Z), making it ideal for simpler jobs. If you’re a beginner or running a small-scale operation, the 3-axis CNC milling machine is a great starting point. - 5-Axis CNC Milling Machine

For more complex parts, a 5-axis CNC milling machine allows for cutting from multiple angles, enabling the creation of highly intricate parts that would otherwise be impossible with a standard machine. Industries requiring this level of precision often use 5-axis CNC milling for aerospace or CNC milling for medical devices. - Vertical CNC Milling Machines

In vertical CNC machines, the spindle is oriented vertically, making them ideal for drilling and machining parts with complex features, such as vertical CNC milling for molds, dies, and smaller parts. - Horizontal CNC Milling Machines

These are equipped with a horizontal spindle that is useful for high-volume machining, especially for larger parts or when working with tough materials. Horizontal CNC milling machines can handle more extensive workloads and are used in industries requiring mass production. - Custom CNC Milling

If you have a specialized need, custom CNC milling can deliver tailored solutions. Custom milling allows businesses to get unique parts designed to their exact specifications, whether it’s for a CNC milling machine part for industrial equipment or a unique CNC milling tool holder.

CNC Milling Services: Benefits & Applications

In addition to purchasing CNC milling machines, many businesses turn to CNC milling services to fulfill specific machining needs. Here are some reasons why CNC milling services are so popular:

- Precision and Quality

The most significant advantage of CNC milling is the ability to produce parts with extremely high accuracy. Whether you’re working with aluminum CNC milling or CNC milling steel, the results are consistently precise. - Custom CNC Milling

If your project requires specialized parts that cannot be produced using standard manufacturing methods, custom CNC milling is the solution. You can design unique parts tailored to your exact specifications, whether it’s a CNC milling machine part for industrial equipment or a unique CNC milling tool holder. - CNC Milling for Rapid Prototyping

One of the key advantages of CNC milling over traditional methods is its capability for rapid prototyping. It allows designers and engineers to test out multiple designs quickly and efficiently. For example, CNC milling companies like those offering precision CNC milling services can provide prototypes to test in the real world before committing to mass production. - Multi-Axis CNC Milling Services

If you’re working on complex projects, 5-axis CNC milling services are invaluable. With the ability to rotate along multiple axes, it provides the flexibility required for highly detailed parts.

CNC Milling Processes

Once the material is selected, the CNC milling process begins. CNC milling involves several stages, from part design to the actual machining process. Over the years, I’ve realized that understanding these steps is crucial for getting the most out of CNC milling, whether you’re working with a mini CNC milling machine or a high-end 5-axis CNC milling machine.

- Design and CAD Modeling

The first step in CNC milling is designing the part using CAD (Computer-Aided Design) software. The design is then converted into G-code, the language that tells the CNC machine exactly how to cut the material. I’ve seen countless times how precision in the design phase is essential—any mistakes made here can lead to costly errors during the machining process. - Material Setup and Machine Calibration

Once the design is ready, the material is secured to the CNC milling machine bed. The machine must be calibrated for the specific part, ensuring the right tools are used, the correct speed and feed rates are set, and the part’s dimensions are aligned. - Machining

In the machining phase, the CNC machine begins to cut the material based on the programmed instructions. The process involves CNC milling cutters rotating at high speeds to remove material from the workpiece. Depending on the complexity, the machine may use various tools to make the necessary cuts. - Finishing and Quality Control

After the milling process is complete, the part undergoes finishing steps, including deburring, cleaning, and sometimes surface treatments. I’ve learned that quality control is essential here—checking for tolerance and surface finish ensures that the part meets all specifications.

Choosing the Right CNC Milling Service

Selecting the best CNC milling service can make or break your project, whether you need CNC milling parts for a prototype or high-volume production. Over the years, I’ve found that working with the right service provider ensures better results and faster turnaround times. Here are some key factors to consider:

- Experience and Expertise

Choose a CNC milling company with a proven track record. A company that specializes in precision CNC milling services or custom CNC milling will be more capable of handling complex projects. It’s important that the provider has experience working with your specific material and part type. - Machine Capability

Depending on your needs, ensure the CNC milling company has the right machines for your project. For highly detailed parts, look for companies that offer 5-axis CNC milling or CNC vertical milling. If you require rapid prototyping, a desktop CNC milling machine or 3-axis CNC milling machine might be more appropriate. - Lead Time and Cost

Always inquire about the lead time and costs associated with the CNC milling service. In my experience, transparent pricing and clear communication about deadlines are vital to maintaining smooth operations. Make sure the service can meet your required production schedule without compromising quality. - Customization Options: Many projects require custom CNC milling solutions, whether it’s creating unique parts or small-batch runs. If your project involves unique designs or specific performance requirements, ensure the milling service can accommodate these needs.

The Future of CNC Milling

Looking ahead, CNC milling is poised to continue evolving. With advances in technology, new types of CNC milling machines and cutting-edge CNC milling software are improving speed, accuracy, and flexibility. One of the most exciting developments is the growing use of additive manufacturing in conjunction with CNC milling. Combining traditional subtractive machining with 3D printing allows for hybrid manufacturing, where parts can be built up with material and then refined using CNC milling. This opens up new possibilities for creating complex, high-performance parts at a faster rate.

Additionally, smart CNC milling machines with integrated sensors and artificial intelligence (AI) are improving the automation and monitoring of the milling process. This leads to more efficient operations and higher-quality results with less human intervention.

FAQs: CNC Milling Machines and Services

- What is the cost of a CNC milling machine?

The cost of CNC milling machines varies widely depending on the complexity and type. For example, desktop CNC milling machines might cost anywhere from $1,000 to $10,000, while 5-axis CNC milling machines can range from $50,000 to over $100,000. It’s crucial to align your budget with the needs of your project.

- How do I select the best CNC milling machine for my needs?

Selecting the right CNC milling machine depends on factors like part complexity, material, and volume. For intricate parts, 5-axis CNC milling machines are the best choice, but for simpler operations, a 3-axis CNC milling machine may suffice. Consider consulting with a CNC milling company for expert advice.

- Can I find CNC milling services near me?

Yes, you can find local CNC milling companies, especially in regions like Savannah or Georgia, which are hubs for manufacturing. A quick online search for CNC milling services near me will provide options for nearby providers.

- What is the difference between CNC milling and CNC turning?

While both CNC milling and CNC turning involve removing material from a workpiece, CNC milling uses a rotating cutter while the part is stationary. CNC turning, on the other hand, involves rotating the workpiece while a stationary cutting tool shapes the material. The two methods are often combined in CNC milling and turning services for complex parts.

- What types of industries use CNC milling?

CNC milling is used across many industries, including aerospace, automotive, medical devices, electronics, and even hobbyist projects. Its ability to work with a variety of materials and produce precise parts makes it indispensable in manufacturing.

Conclusion:

CNC milling has become an essential process in precision manufacturing, enabling industries to create high-quality, intricate parts with unmatched accuracy. Whether you’re exploring custom CNC milling, buying a CNC milling machine for sale, or seeking CNC milling services, the key is understanding your project’s requirements and selecting the right solution to meet those needs.

Over the years, I’ve witnessed firsthand how CNC milling evolves to meet the demands of modern manufacturing. From precision CNC milling to rapid prototyping, this technology is a game-changer for businesses seeking efficiency and high-quality results.

If you’re looking for a CNC milling machine, understand your project requirements before making an investment. And if you need expert services, don’t hesitate to reach out to a reliable CNC milling company that can deliver custom solutions to suit your needs.