CNC Turning vs CNC Milling: Understanding the Right Machining Process for Your Project

Explore CNC Turning vs CNC Milling, their processes, costs, accuracy, and applications. Learn which machining method best fits your project.

In precision manufacturing, choosing the right machining process can directly impact part quality, cost efficiency, and production timelines. Two of the most widely used methods—CNC Turning and CNC Milling—are often compared, yet many manufacturers still struggle to decide which one best suits their application.

This guide breaks down CNC Turning vs CNC Milling in clear, practical terms. Whether you’re producing high-volume cylindrical components or complex multi-axis parts, understanding the differences between milling and turning helps you make informed, cost-effective decisions.

At V&S Engineering, we work with both CNC milling and turning technologies daily, supporting industries that demand precision, consistency, and reliability.

What Is CNC Turning?

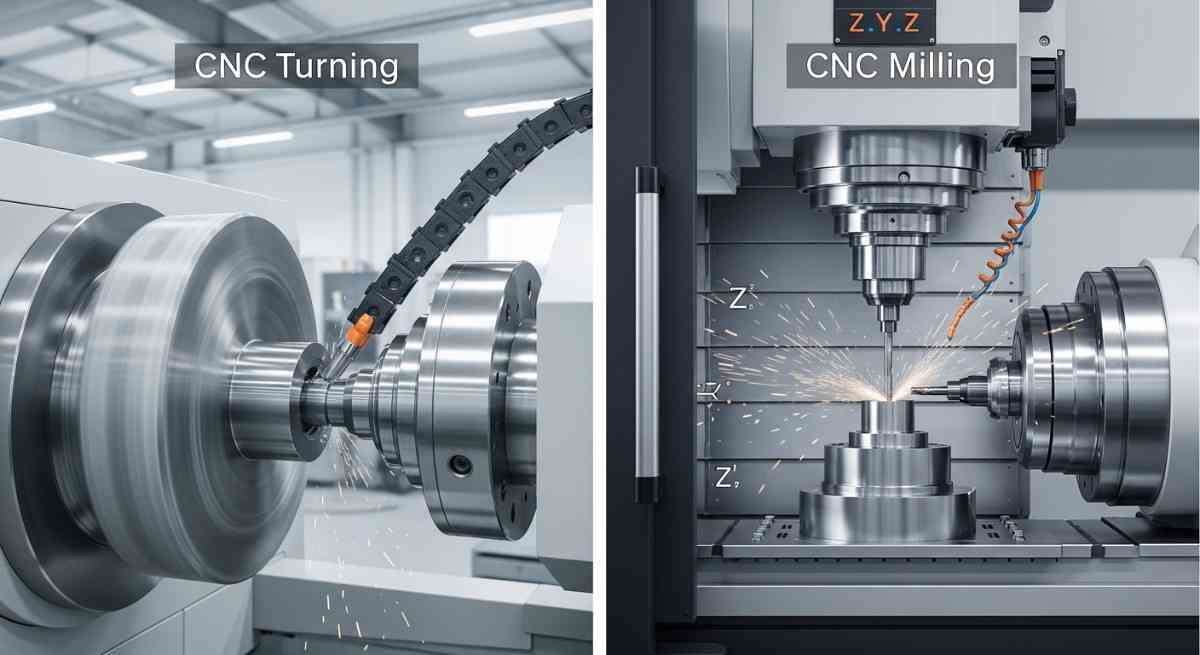

CNC Turning is a machining process where the workpiece rotates while a stationary cutting tool removes material. This process is typically performed on CNC lathes and is ideal for round or symmetrical components.

Key Characteristics of CNC Turning

- Rotating workpiece

- Linear cutting tool movement

- Best for cylindrical and conical shapes

- Efficient for high-volume production

Common CNC Turning Applications

- Shafts and rods

- Bushings and sleeves

- Fasteners and connectors

- Automotive and hydraulic components

CNC turning and milling operations are especially effective when tight tolerances and smooth surface finishes are required on round parts.

What Is CNC Milling?

CNC Milling works differently: the cutting tool rotates, while the workpiece remains stationary or moves along multiple axes. This flexibility allows for more complex geometries and detailed features.

Key Characteristics of CNC Milling

- Rotating cutting tool

- Multi-axis movement (3, 4, or 5-axis)

- Capable of complex shapes

- Ideal for precision detailing

Common CNC Milling Applications

- Housings and enclosures

- Brackets and plates

- Complex aerospace components

- Custom industrial parts

Many manufacturers combine CNC milling and turning to produce parts that require both rotational symmetry and intricate features.

CNC Turning vs CNC Milling: A Detailed Comparison

CNC Milling vs Turning – Side-by-Side Overview

| Feature | CNC Turning | CNC Milling |

| Workpiece Movement | Rotates | Stationary or multi-axis |

| Tool Movement | Linear | Rotational |

| Best For | Cylindrical parts | Complex geometries |

| Production Speed | Faster for round parts | Slower for simple shapes |

| Setup Cost | Lower | Higher |

| Design Flexibility | Limited | High |

Process Differences: Milling vs Turning Explained

- Turning removes material evenly around a rotating part

- Milling removes material from multiple angles using rotating tools

In short, milling and turning decisions depend on part geometry, tolerance needs, and production volume.

Materials Used in CNC Milling and Turning

Both processes can machine a wide range of materials, including:

- Aluminum and aluminum alloys

- Stainless steel

- Carbon steel

- Brass and copper

- Engineering plastics

At V&S Engineering, material selection is optimized based on performance requirements and machining efficiency—whether using CNC milling, turning, or standalone processes.

Accuracy and Tolerances

- CNC Turning excels at maintaining concentricity and diameter precision

- CNC Milling offers superior control for complex features and tight tolerances

Both methods can achieve micron-level accuracy when programmed and executed correctly.

Cost Considerations: CNC Turning vs CNC Milling

CNC Turning Cost Advantages

- Faster cycle times

- Lower tooling complexity

- Ideal for mass production

CNC Milling Cost Considerations

- Higher setup and programming costs

- More flexible for custom parts

- Best for low-to-medium production runs

Choosing between milling and turning often comes down to balancing part complexity with production volume.

Advantages and Limitations of CNC Turning – Pros & Cons

Advantages

- High-speed production

- Excellent surface finish

- Cost-effective for round parts

Limitations

- Limited shape complexity

- Not suitable for intricate features

CNC Milling – Pros & Cons

Advantages

- Highly versatile

- Suitable for complex designs

- Multi-axis capability

Limitations

- Higher operational costs

- Longer machining times

Why Manufacturers Choose V&S Engineering

V&S Engineering brings hands-on expertise in CNC milling and turning, delivering precision-machined components that meet strict quality standards across industries. Our engineering-first approach ensures every project uses the most efficient machining strategy—without unnecessary cost or compromise.

Frequently Asked Questions (FAQ)

1. What is the main difference between CNC turning and CNC milling?

The primary difference is movement: CNC turning rotates the workpiece, while CNC milling rotates the cutting tool.

2. Which is better: milling or turning?

Neither is universally better. Milling vs turning depends on part geometry, tolerance, and production volume.

3. Can a single part require both CNC milling and turning?

Yes. Many components are produced using combined CNC milling and turning operations for optimal results.

4. Which process is more cost-effective?

CNC turning is generally more cost-effective for cylindrical, high-volume parts, while milling is better for complex shapes.

5. What industries use CNC turning and milling services?

Automotive, aerospace, medical devices, energy, and industrial manufacturing all rely on CNC turning milling solutions.

Conclusion: CNC Turning vs CNC Milling – Which Should You Choose?

Choosing between CNC Turning vs CNC Milling isn’t about selecting the “better” process—it’s about selecting the right one for your application. Turning excels in speed and efficiency for round components, while milling offers unmatched flexibility for complex designs.

For manufacturers seeking precision, reliability, and expert guidance, partnering with an experienced CNC machining provider makes all the difference. With deep expertise in milling and turning, V&S Engineering helps you achieve optimal performance, quality, and value—every time.