What Is Delrin?

What is Delrin plastic? Learn about Delrin material properties, uses, advantages, comparisons, and suppliers in this in-depth guide for engineers and industrial buyers.

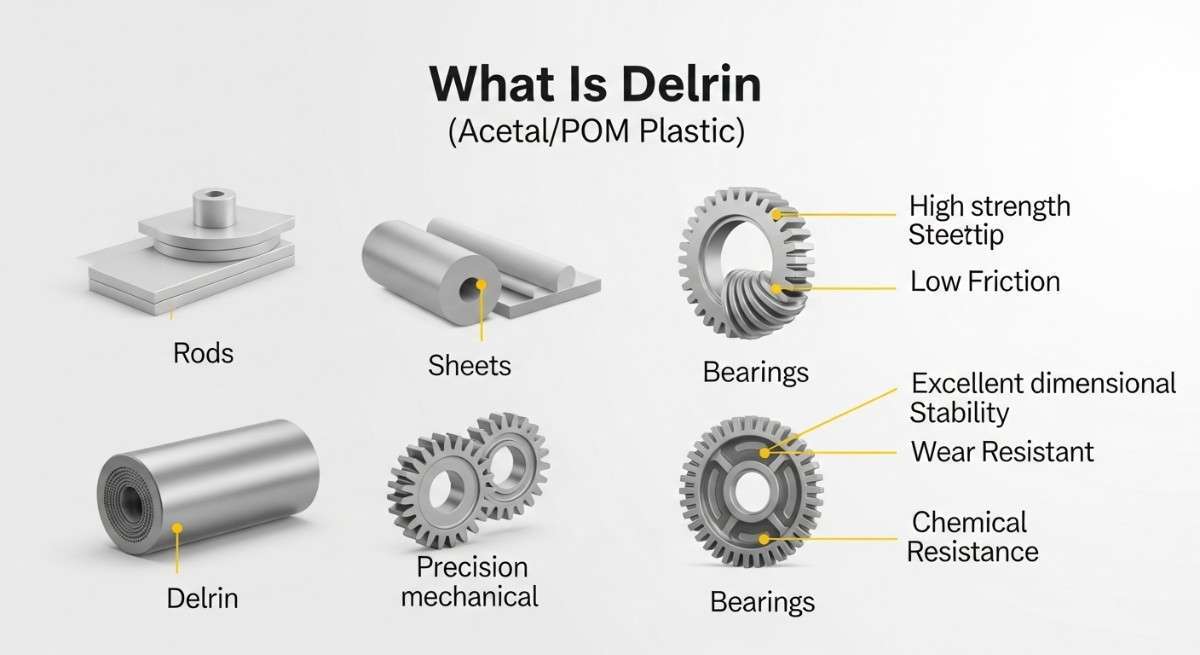

Delrin is one of the most widely used engineering plastics in modern manufacturing, known for its exceptional strength, precision, and reliability. Often selected as a replacement for metal, Delrin plastic material offers a unique combination of high mechanical performance, low friction, and excellent dimensional stability, making it ideal for demanding industrial applications.

If you are an engineer, OEM, or procurement professional searching for a durable plastic that performs consistently under load, this guide explains what Delrin is, how it works, where it is used, and how it compares to other engineering plastics.

What Is Delrin Plastic?

Delrin is the brand name for acetal homopolymer, also referred to as POM-H (polyoxymethylene homopolymer). It is a semi-crystalline thermoplastic developed for applications that require tight tolerances, smooth motion, and long service life.

As a Delrin polymer, it stands out for its ability to maintain mechanical strength and shape even when exposed to repeated stress, temperature changes, and moisture. This makes Delrin acetal plastic a preferred material in precision engineering environments where failure is not an option.

Understanding Delrin Material and Resin Composition

Delrin resin is produced through a controlled polymerization process that results in a highly ordered crystalline structure. This structure is responsible for many of the material’s defining characteristics, including rigidity, wear resistance, and fatigue endurance.

Because of its molecular uniformity, Delrin plastic material delivers predictable performance, which is essential in CNC machining, injection molding, and extrusion. Manufacturers rely on this consistency when producing parts that must meet strict dimensional and mechanical specifications.

Delrin Material Properties Explained

Delrin properties place it among the highest-performing engineering plastics available today.

Mechanical Properties

Delrin mechanical properties include high tensile strength, excellent stiffness, and strong resistance to fatigue and creep. These qualities allow Delrin components to carry loads over long periods without permanent deformation, even in moving assemblies.

Thermal Properties

Delrin thermal properties enable stable performance across a wide temperature range. While it is not designed for extreme heat environments, it maintains structural integrity in typical industrial operating conditions and resists thermal expansion better than many plastics.

Chemical Resistance

Delrin plastic resists fuels, oils, greases, and many solvents, making it suitable for mechanical and automotive environments. However, it should not be exposed to strong acids, strong bases, or continuous hot water or steam, as these can degrade the material.

Machining Properties

One of the biggest advantages of Delrin is its machinability. Delrin machining properties allow for clean cuts, minimal tool wear, and excellent surface finishes. It is commonly CNC machined into complex parts with tight tolerances, reducing production time and scrap rates.

What Is Delrin Used For?

Because of its balanced performance, Delrin is used across a wide range of industries.

In industrial and mechanical applications, Delrin plastic uses include gears, bearings, bushings, rollers, cams, and pump components. These parts benefit from Delrin’s low friction and wear resistance.

In the automotive industry, Delrin is used for door lock mechanisms, seat belt components, fuel system parts, and precision clips. Its durability and dimensional stability help ensure consistent performance over millions of cycles.

Electrical and electronics manufacturers rely on Delrin for connectors, housings, insulators, and covers due to its insulating properties and strength. In medical and consumer products, Delrin is often found in drug-delivery devices, precision housings, and food-contact mechanical components.

Delrin Homopolymer vs Copolymer

A common question among buyers is the difference between Delrin homopolymer and acetal copolymer.

Delrin homopolymer offers higher tensile strength, greater stiffness, and better fatigue resistance. It also provides a smoother surface finish, which is important for sliding or visible components.

Acetal copolymer, while slightly weaker, provides improved resistance to hot water and chemicals and is sometimes easier to process. The choice depends on whether mechanical performance or chemical resistance is the primary requirement.

Advantages and Disadvantages of Delrin

Delrin advantages include its high strength-to-weight ratio, excellent wear resistance, low friction, tight tolerance capability, and long service life. These benefits often justify its higher cost compared to commodity plastics.

However, Delrin disadvantages should also be considered. The material has poor UV resistance, making it unsuitable for long-term outdoor exposure without protection. It is also difficult to bond using standard adhesives and can deform if overheated during machining.

Delrin vs Other Engineering Plastics

When comparing materials, Delrin often stands out.

Compared to nylon, Delrin absorbs far less moisture and maintains better dimensional stability. When evaluated against PTFE, Delrin offers significantly higher strength and machinability, though PTFE has lower friction. Against ABS plastic, Delrin delivers far superior mechanical performance and durability. Compared to PVC, Delrin is stronger and more precise, making it better suited for mechanical parts rather than piping.

Understanding these differences helps engineers select the most cost-effective material for each application.

Buying Delrin Plastic: Suppliers and Global Availability

Delrin is available worldwide in the form of sheets, rods, tubes, and custom-machined components. Buyers often search for reliable Delrin plastic suppliers, Delrin sheet suppliers, or Delrin rod suppliers to ensure consistent quality and material traceability.

Industrial demand is particularly strong among Delrin suppliers in the USA, Canada, Germany, and Japan, where Delrin is widely used in automotive, precision engineering, electronics, and industrial manufacturing sectors. Pricing varies depending on grade, form, and volume, so evaluating Delrin material price alongside performance requirements is essential.

FAQ’s

What is Delrin plastic?

Delrin is an acetal homopolymer engineering plastic known for high strength, low friction, and dimensional stability.

What are the main Delrin applications?

Delrin is used in gears, bearings, automotive parts, electrical components, and precision mechanical assemblies.

Is Delrin stronger than nylon?

Yes, Delrin offers higher stiffness, better fatigue resistance, and lower moisture absorption than nylon.

Can Delrin be CNC machined?

Yes. Delrin is one of the best plastics for CNC machining due to its stability and clean cutting behavior.

What is the difference between acetal and Delrin?

Delrin is an acetal homopolymer (POM-H) and provides higher mechanical performance than acetal copolymer (POM-C).

Where can I buy Delrin plastic?

Delrin can be sourced from plastic manufacturers and suppliers across the USA, Canada, Germany, and Japan in sheets, rods, and custom parts.

Conclusion

Delrin is a premium engineering plastic that combines strength, precision, and reliability in a way few materials can match. Its excellent mechanical performance, ease of machining, and proven track record across industries make it a trusted choice for high-performance components worldwide.

For manufacturers and buyers seeking a long-lasting, precision plastic solution, Delrin plastic material remains one of the most dependable options available today.