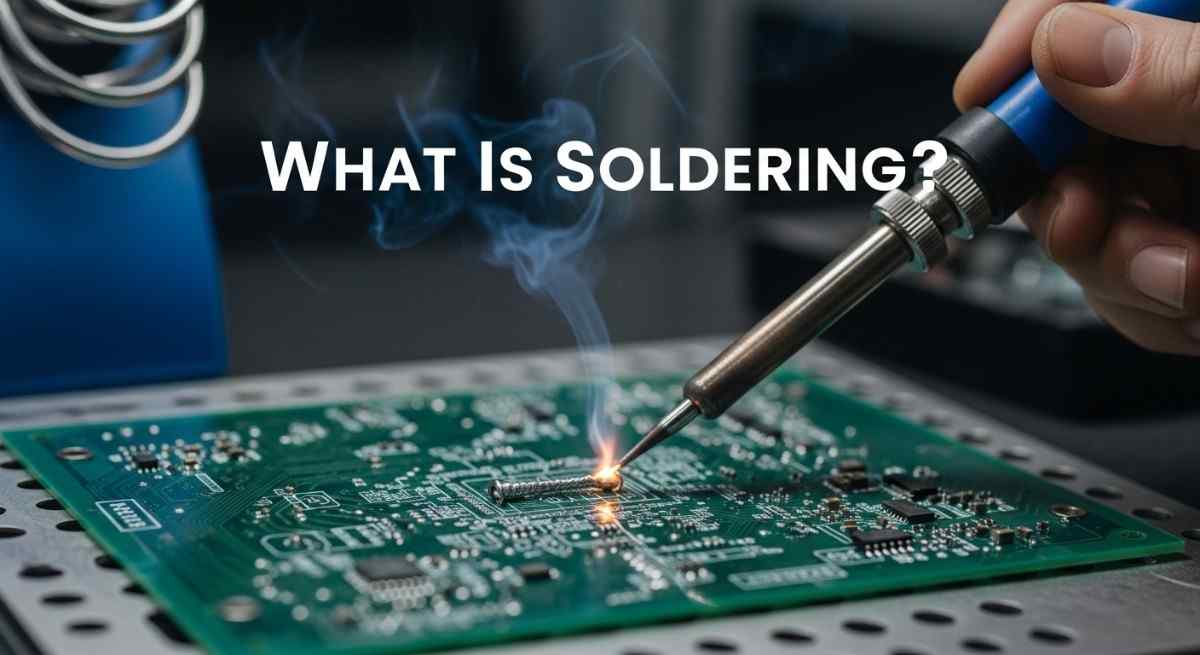

What Is Soldering?

What is soldering? Learn the soldering process, types of soldering, tools, and why soldering is critical for reliable connections.

Soldering is one of the most critical joining processes in modern manufacturing, electronics, and industrial production. From printed circuit boards (PCBs) to aerospace systems and medical devices, soldering enables reliable electrical connectivity, mechanical stability, and long-term performance—without damaging sensitive components.

For manufacturers, engineers, and industrial buyers, understanding what soldering is, how it works, and which techniques to use is essential for ensuring product quality, compliance, and operational efficiency.

This guide explains soldering clearly, practically, and professionally—covering definitions, processes, types, tools, applications, and why soldering remains indispensable in global industries.

Soldering Meaning

Soldering is a metal-joining process in which a low-melting-point filler metal (called solder) is melted and flowed between two or more metal surfaces. Once cooled, the solder solidifies to form a durable, conductive joint.

Unlike welding, soldering does not melt the base metals. This lower-temperature process makes soldering ideal for electronics, fine metal assemblies, and applications where heat control is critical.

In practical terms, when metals are soldered, they become electrically connected, mechanically bonded, and capable of withstanding operational stress within their intended environment.

How the Soldering Process Works

The soldering process is precise and controlled. High-quality solder joints depend on preparation, correct temperature, and proper technique.

1. Surface Preparation

Metal surfaces must be clean and free from oxidation, oils, dust, or residues. Poor surface preparation is one of the most common causes of solder joint failure.

2. Flux Application

Soldering flux is applied to remove oxides and prevent oxidation during heating. Flux enables proper solder wetting, allowing molten solder to flow evenly and bond securely.

3. Controlled Heating

Heat is applied using a soldering iron, soldering station, or soldering gun, depending on the application. The joint—not the solder—is heated to ensure uniform flow and penetration.

4. Solder Application

Once the joint reaches the correct temperature, solder is introduced. The molten solder flows into the joint through capillary action, forming a continuous bond.

5. Cooling and Inspection

The joint cools naturally, creating a solid electrical and mechanical connection. Proper inspection confirms smooth fillets, full wetting, and absence of defects.

Types of Soldering

Different soldering techniques are used depending on temperature requirements, strength needs, and production scale.

Soft Soldering

Soft soldering uses low-melting solder alloys, typically tin-based. It is widely used in:

Electronics and PCB assembly

Electrical wiring

Plumbing and light metalwork

Soft soldering provides excellent electrical conductivity but lower mechanical strength.

Hard Soldering (Silver Soldering)

Hard soldering uses higher-temperature, silver-based alloys to create stronger joints. It is commonly used in:

Industrial metal assemblies

Mechanical components

Applications requiring higher durability

Automated and Industrial Soldering Methods

For large-scale production, manufacturers rely on:

Reflow soldering (surface-mount electronics)

Wave soldering (through-hole PCB assembly)

Dip soldering (mass termination)

Ultrasonic soldering (difficult-to-bond metals)

Soldering vs Welding vs Brazing

Understanding the difference between joining methods is critical for selecting the right process:

Soldering: Low temperature, no base-metal melting, ideal for electronics

Welding: High temperature, base metals melt, structural strength

Brazing: Higher temperature than soldering, strong joints, industrial piping and repair

Soldering is preferred when precision, conductivity, and component safety are priorities.

Soldering Tools and Equipment

Successful soldering depends on using the right tools for the job.

Common Soldering Equipment

Soldering iron

Soldering station with temperature control

Soldering gun for high-heat applications

Soldering tips (various geometries)

Solder wire and solder alloys

Soldering flux

Desoldering tools for rework and repair

Industrial production environments often use reflow ovens, wave soldering machines, and automated soldering systems to maintain consistency and throughput.

Soldering Applications Across Industries

Soldering is essential in industries where performance, reliability, and compliance are non-negotiable.

Key Industries Using Soldering

Electronics and PCB manufacturing

Aerospace and avionics

Automotive electronics

Medical device manufacturing

Telecommunications

Industrial automation

HVAC and electrical infrastructure

In electronics, soldering ensures stable signal transmission, thermal efficiency, and long-term operational reliability.

Benefits and Importance of Soldering

Soldering remains a preferred joining method because it offers:

Excellent electrical conductivity

Low thermal stress on components

High precision for small and complex assemblies

Repairability and rework capability

Cost-effective scalability

Compliance with international manufacturing standards

For industrial buyers and manufacturers, soldering directly impacts product lifespan, safety, and customer satisfaction.

FAQ’s

What is soldering used for?

Soldering is used to join metal components, especially in electronics, electrical systems, and precision manufacturing.

What tools do you need for soldering?

At minimum: a soldering iron, solder wire, flux, and safety equipment. Industrial soldering uses automated systems and temperature-controlled stations.

What is the difference between soldering and welding?

Soldering uses lower heat and does not melt base metals, making it ideal for electronics. Welding melts base metals for structural applications.

Why is soldering flux necessary?

Flux removes oxidation, improves solder flow, and ensures strong, reliable solder joints.

Is soldering safe?

Yes, when proper ventilation, temperature control, and safety practices are followed.

Conclusion

Soldering is not just a manufacturing step—it is a critical quality process that determines the reliability and performance of countless products used every day. From advanced electronics to industrial systems, precision soldering ensures components function as designed, safely and consistently.

For businesses that demand high-quality results, working with experienced soldering professionals and reliable suppliers is essential.

Contact a trusted soldering expert today to discuss your requirements, production needs, or technical challenges.