Assembly and Kitting Service

At V&S Engineering, we specialize in providing top-tier assembly and kitting services to streamline production workflows, enhance efficiency, and help businesses meet their manufacturing demands effectively. Our solutions ensure accuracy, reduce production delays, and improve overall operational efficiency.

Assembly And Kitting Services

At V&S Engineering, we provide professional assembly and kitting services that help manufacturers simplify operations, reduce lead times, and maintain consistent product quality. Our services are designed to support high-precision, export-ready manufacturing for clients across the USA, Canada, Germany, and Japan.

By combining structured assembly processes with accurate kitting, we ensure your components arrive organized, complete, and ready for production or delivery.

What Are Assembly & Kitting Services?

Assembly involves joining individual components into a complete, functional product or sub-assembly.

Kitting is the process of grouping all required parts into a single, organized kit before assembly or shipment.

When combined, assembly and kitting:

- Reduce production downtime

- Improve workflow efficiency

- Minimize assembly errors

- Simplify inventory and logistics

This integrated approach is essential for modern, high-volume manufacturing environments.

Why Assembly & Kitting Matter in Manufacturing

Well-executed assembly and kitting directly impact production performance and cost control.

Key Benefits Include:

- Improved Product Consistency – Every unit assembled to the same standard

- Shorter Lead Times – Faster assembly through pre-organized components

- Reduced Handling Errors – Fewer missing or incorrect parts

- Optimized Labor Efficiency – Assembly teams focus on value-added work

These advantages are especially important for global supply chains and export-oriented production.

Our Assembly & Kitting Capabilities

We offer flexible solutions tailored to your product, volume, and industry requirements.

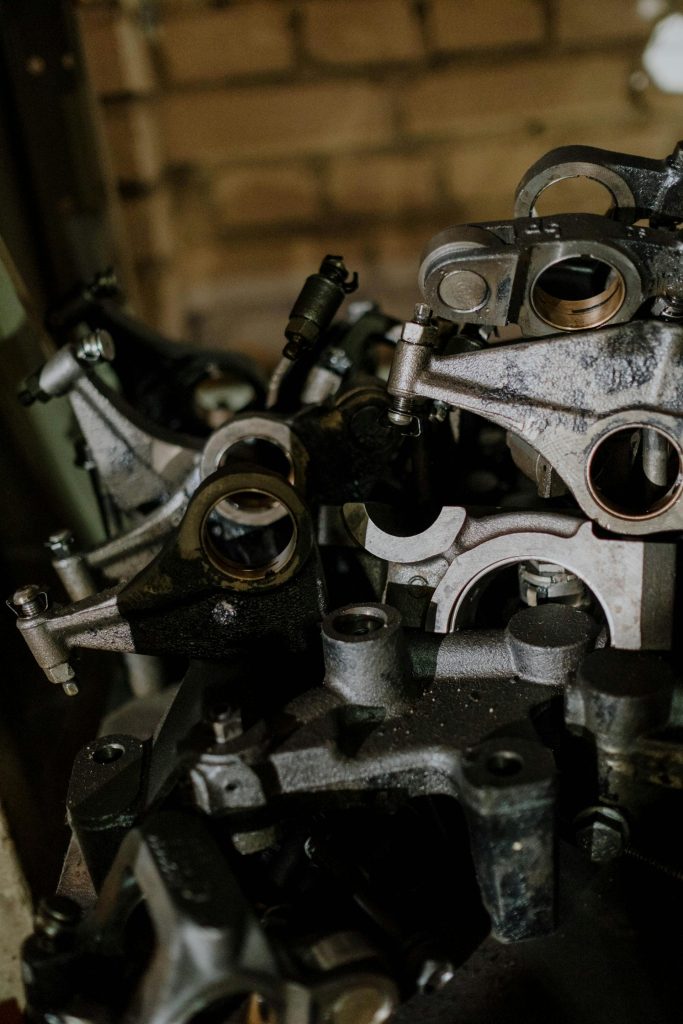

Assembly Services

- Mechanical and component assembly

- Sub-assembly and final product assembly

- Assembly according to drawings, BOMs, and specifications

- Scalable support for low to high production volumes

Kitting Services

- BOM-based component grouping

- Labeling and identification for easy traceability

- Custom packaging based on client or logistics requirements

- Assembly-ready and shipment-ready kits

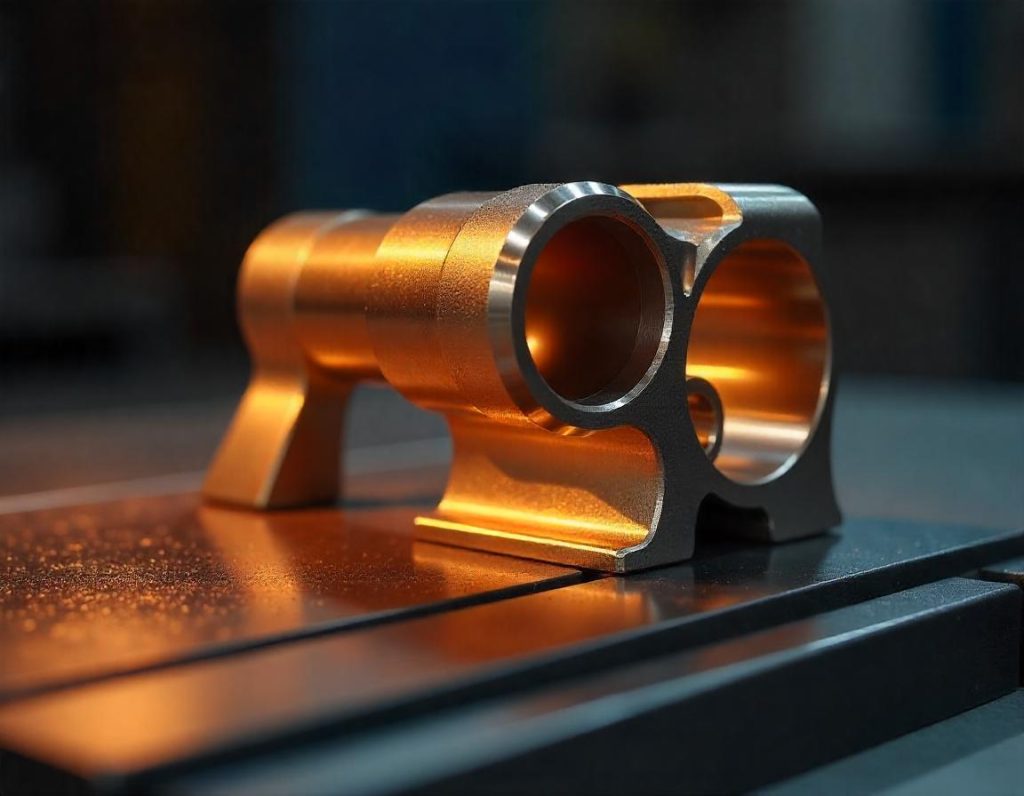

Each process is carefully controlled to ensure accuracy, repeatability, and reliability.

The Role of Technology in Assembly & Kitting

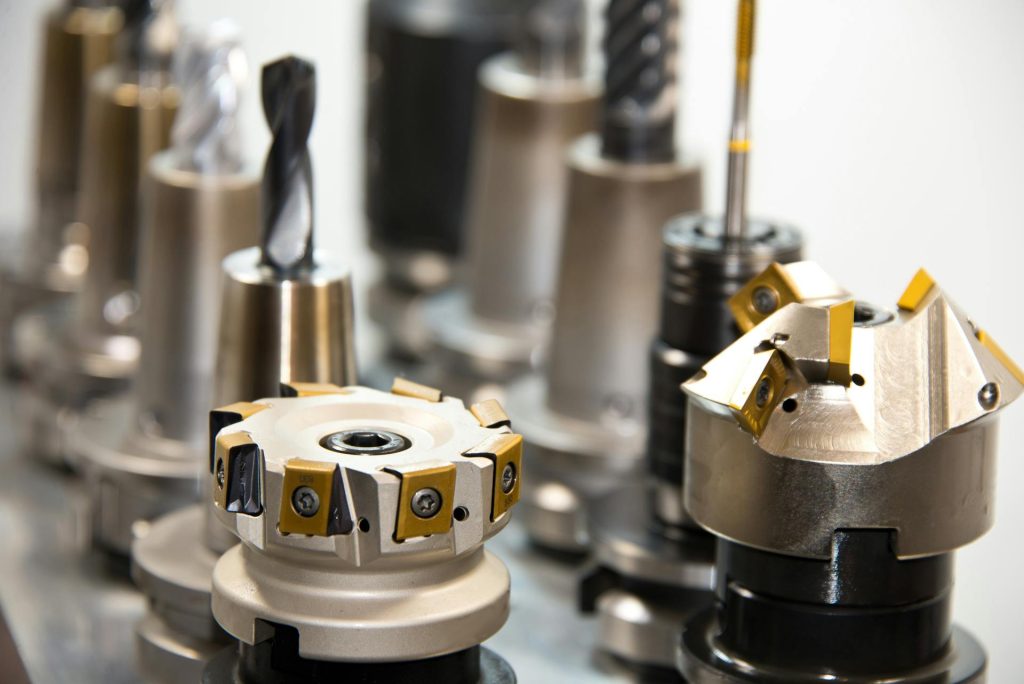

Technological advancements have revolutionized assembly and kitting, improving efficiency and precision. Key innovations include:

- Automated Assembly Lines: Enhancing speed and reducing human error.

- Inventory Management Software: Real-time tracking to prevent stock discrepancies.

- AI-Powered Quality Control: Detecting defects early in the assembly process.

Leveraging technology ensures consistency and optimizes production workflows.

Benefits of Outsourcing Assembly Services

Companies outsourcing assembly and kitting services experience several advantages:

- Cost Reduction: Eliminating the need for in-house infrastructure and labor.

- Scalability: Adapting to fluctuating production demands with ease.

- Expert Handling: Relying on specialists to maintain high-quality standards.

Outsourcing these services allows businesses to focus on their core competencies while ensuring efficient production.

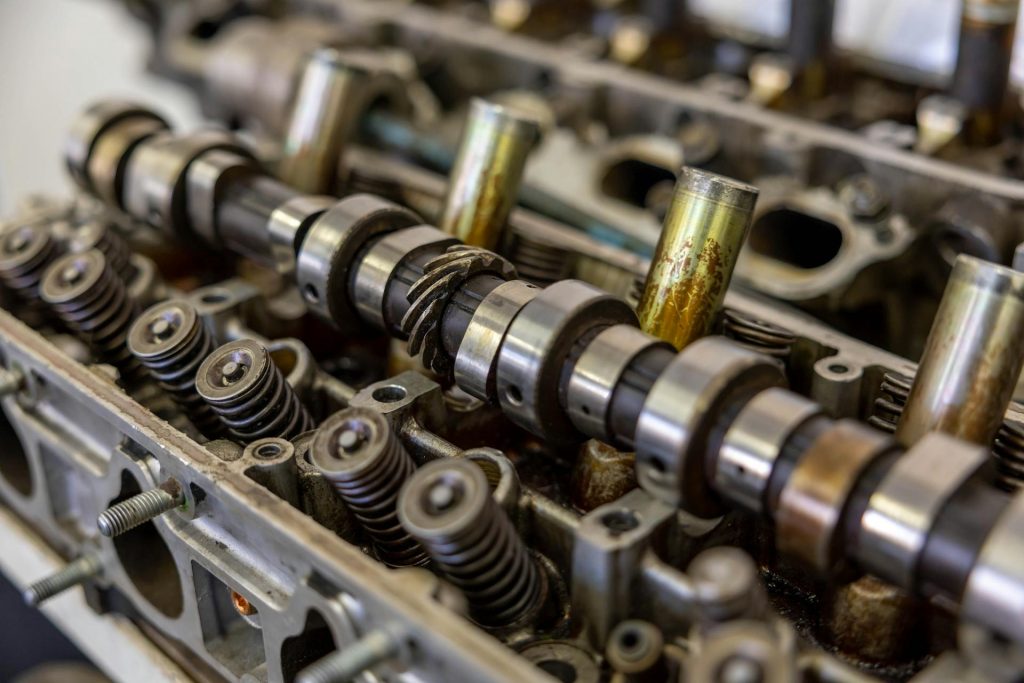

Quality Control Measures in Assembly & Kitting

Ensuring high-quality output in assembly and kitting requires strict control measures, including:

- Inspection & Testing: Identifying defects before final production.

- Standardized Processes: Following industry best practices to maintain consistency.

- Workforce Training: Equipping employees with the skills to meet quality expectations.

By implementing thorough quality checks, we guarantee reliable and defect-free products.

Common Challenges in Assembly & Kitting

Despite the advantages, challenges such as inventory discrepancies, equipment failures, and workforce training can arise. Overcoming these challenges involves:

- Investing in Reliable Systems: Automating tracking and quality assurance.

- Workforce Development: Training employees to operate efficiently.

- Proactive Maintenance: Ensuring equipment is in optimal condition to prevent downtime.

Addressing these factors improves operational efficiency and prevents costly delays.

Future Trends in Assembly & Kitting

The future of assembly and kitting is evolving with:

- Increased Automation: Utilizing robotics and AI for precision assembly.

- Sustainable Practices: Reducing waste through optimized processes.

- Smart Warehousing: Leveraging IoT for real-time inventory tracking.

Companies that adopt these trends will improve efficiency, reduce costs, and enhance sustainability.

Case Studies of Successful Assembly & Kitting Implementation

Real-world applications of assembly and kitting highlight the tangible benefits of optimized processes. Examples include:

- Electronics Manufacturer: Reduced assembly time by 40% through improved kitting procedures.

- Automotive Supplier: Streamlined part packaging, reducing production delays by 30%.

- Medical Device Firm: Enhanced quality control measures to meet strict industry standards.

These case studies demonstrate the impact of well-executed assembly and kitting strategies.

Why Choose V&S Engineering?

At V&S Engineering, we bring precision, efficiency, and reliability to every assembly and kitting project. Our services offer:

- End-to-End Solutions: From kitting preparation to final assembly.

- State-of-the-Art Facilities: Utilizing advanced technology for optimal results.

- Custom Solutions: Tailored to meet specific industry needs.

Contact us today to learn how our assembly and kitting services can enhance your manufacturing process and streamline your supply chain.