CNC Machining

Explore CNC machining, the backbone of modern manufacturing. Learn how CNC machines work, their uses, and the many processes that make them essential in today’s industries.

When you hear about CNC machining, you’re likely thinking about robots in factories, complex parts being manufactured with extreme precision, and technology that is miles ahead of traditional methods. But here’s the thing: CNC machining has been around for decades, and while it’s evolved tremendously, it’s still rooted in the simple principle of precision engineering.

I’ve been in this field long enough to see both the struggles and triumphs associated with CNC machining, and let me tell you, the difference between a good CNC machine operator and a great one is more than just technical know-how. It’s about understanding how these machines can transform raw material into a high-quality product while keeping costs down and timelines tight.

Let’s dig into how CNC machining works and why it’s an absolute game-changer in manufacturing, based on real-world experience.

What is CNC Machining?

When people ask, “What is CNC machining?” I tell them it’s the process that uses computer numerical control to manage machines and tools in a manufacturing environment. What’s really fascinating about this process is how it revolutionizes machining by automating tasks that were once labor-intensive and prone to error.

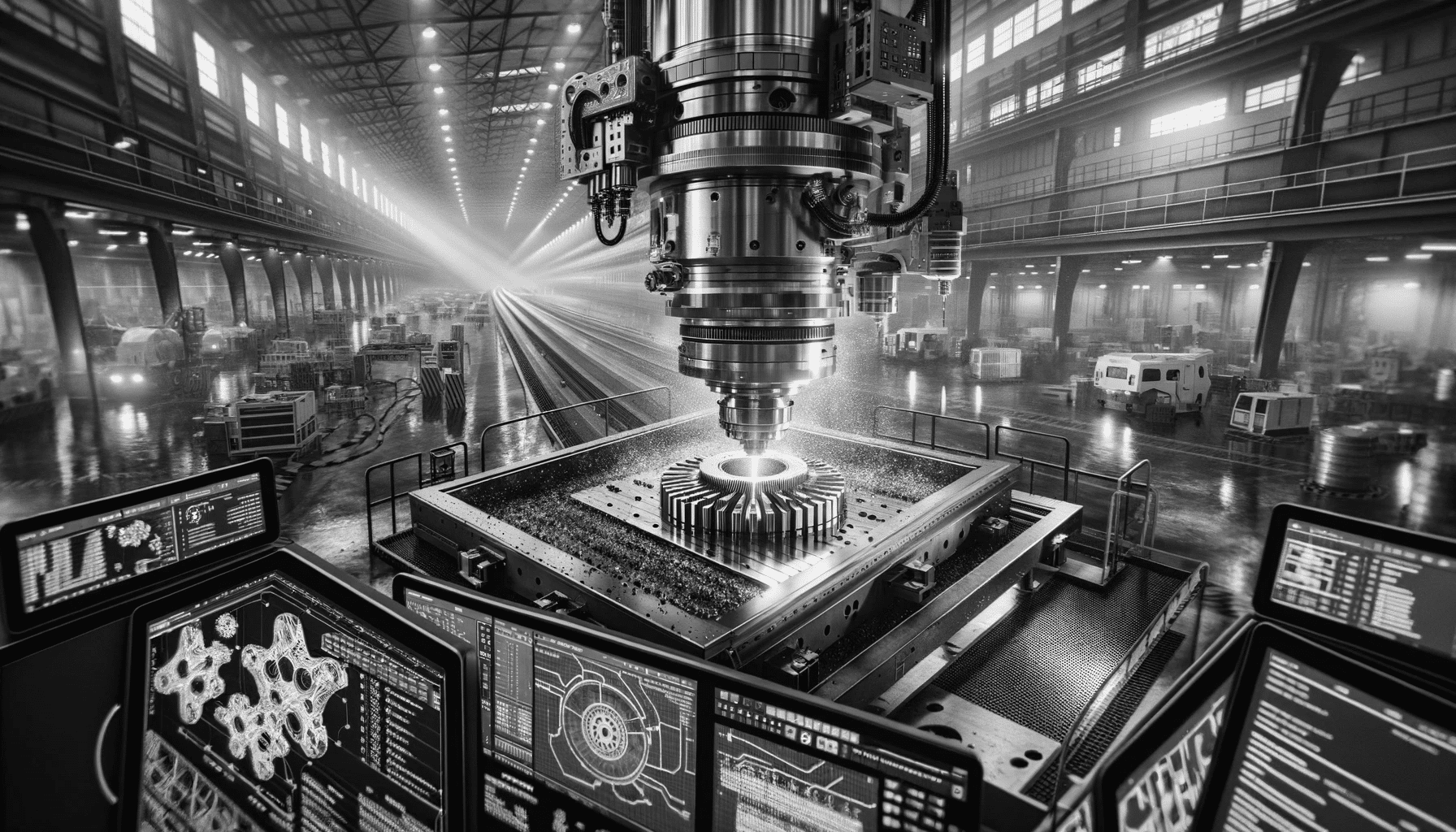

In simple terms, CNC machining involves a CNC machine, which is essentially a computer-controlled tool that can cut, mill, drill, or shape material according to pre-programmed specifications. But here’s the kicker: the precision and speed that CNC machines bring are nearly impossible for traditional manual methods to replicate.

I’ve worked with various types of CNC machinery—from simple CNC lathes to complex CNC milling machines—and seen firsthand how it accelerates production while ensuring consistently high-quality output.

How Does CNC Machining Work?

CNC machining operates on a highly automated system that starts with a design, usually created in CAD (Computer-Aided Design), which is then translated into a set of commands (G-code). This G-code tells the CNC machine what to do: where to move, what speed to use, and what tools to employ. It’s almost like giving the machine a set of instructions, and it does the work for you.

Step-by-Step Process:

- Design Creation: The first step is designing the part using CAD software. The design can be anything from a simple part to a highly complex aerospace component.

- Conversion to G-code: Once the design is ready, it’s converted into G-code using CAM (Computer-Aided Manufacturing) software. The G-code is a set of instructions that tells the CNC machine how to perform operations like cutting, drilling, or turning.

- Setup: The CNC machine is prepared by securing the material and loading the necessary tools. This setup is critical because even a slight misalignment can affect the precision of the final part.

- Machining Process: With the setup complete, the CNC machine takes over. The machine follows the G-code to execute various operations like drilling, milling, or turning, depending on the type of machine and task at hand.

- Finishing: Once the part is machined, it often undergoes finishing operations like polishing or coating to meet the required specifications.

Real-Life Example:

I recall a project where we were manufacturing aerospace parts using CNC machining. The material was tough, and the dimensions had to be exact. We were using CNC turning to shape the outer features and CNC milling to make precise internal cuts. The project was critical, and mistakes weren’t an option. The precision of the CNC machine allowed us to meet tight tolerances and deliver parts on time. The fact that the machine could repeat the process without error—over and over—was invaluable.

CNC Machines in Action

What Are CNC Machines?

CNC machines are mechanical tools that are operated by a computer system, designed to perform a variety of operations. There are several types, such as CNC milling machines, CNC lathes, CNC routers, and CNC grinders. Each type is designed for specific tasks, whether it’s cutting, milling, or turning material into complex parts.

Common Types of CNC Machines:

- CNC Milling Machines: These machines use rotary cutters to remove material from a workpiece.

- CNC Lathes: Used for turning operations, CNC lathes rotate the material to cut it into shape.

- CNC Routers: Typically used for cutting large sheets of material, such as wood, plastic, or soft metals.

- CNC Grinders: These machines are used for precision grinding tasks, often needed for producing smooth finishes or sharpening parts.

What Does CNC Mean in Manufacturing?

In CNC manufacturing, the term “CNC” stands for Computer Numerical Control. It means that the entire manufacturing process—whether it’s CNC metalworking, CNC production machining, or CNC processes—is managed and controlled by computer software. This results in faster production, increased precision, and less waste.

CNC machines are incredibly versatile, allowing manufacturers to produce a wide range of parts for CNC machining manufacturing operations. Whether it’s for aerospace, automotive, medical devices, or consumer electronics, CNC technology is indispensable for producing parts with the accuracy required to meet exact specifications.

CNC Machining Process: Benefits and Advantages

- High Precision and Accuracy: CNC machines can create parts with extreme accuracy. The machine doesn’t experience fatigue or loss of focus, meaning it can maintain consistent precision across all parts.

- Speed and Efficiency: Once set up, CNC machines can produce parts quickly. They run continuously, with minimal human intervention, which is a major benefit for mass production.

- Flexibility: CNC machines are capable of executing a wide range of processes like CNC milling, CNC turning, CNC drilling, and CNC grinding, making them versatile for various types of parts.

- Reduced Labor Costs: While the initial setup cost of CNC machinery can be high, the labor costs are significantly reduced because the process is automated.

Advancements in CNC Machining Technology

The world of CNC machining is continuously evolving. Recent technological advancements have further enhanced the capabilities of CNC machines, making them even more efficient, flexible, and precise.

1. 5-Axis CNC Machining

Traditionally, CNC machines operated in 3 axes (X, Y, and Z), moving along three directions. However, 5-axis CNC machines take things to the next level. These machines can move the workpiece or tool along five axes simultaneously, allowing for more complex shapes and better angles of cutting. This capability is especially beneficial for industries such as aerospace, where intricate, multi-dimensional parts are required.

Using a 5-axis CNC machine, you can achieve superior accuracy and eliminate the need for multiple setups, reducing the overall production time.

2. CNC Laser Cutting and 3D Printing

CNC laser cutting and 3D printing are exciting developments in CNC technology. While CNC laser cutting uses a high-powered laser to cut or engrave materials with high precision, 3D printing (additive manufacturing) allows for the creation of parts layer by layer. This is particularly useful in producing prototypes or small production runs with intricate designs that are too complex for traditional machining.

Both CNC laser cutting and 3D printing offer the ability to produce customized parts with speed and minimal waste, revolutionizing how prototypes and even final products are manufactured.

3. Smart CNC Machines and IoT Integration

The next big leap in CNC machining lies in smart manufacturing. Modern CNC machines are increasingly being equipped with IoT (Internet of Things) sensors that allow them to communicate in real-time with other systems in the factory. This integration helps manufacturers monitor machine performance, detect faults before they occur, and gather data on every step of the production process.

With smart CNC machines, you can achieve predictive maintenance, reduce downtime, and further optimize production schedules.

Industries That Benefit from CNC Machining

CNC machining isn’t limited to just one sector; its versatility spans across various industries. Here’s a look at how different fields benefit from CNC technology:

1. Aerospace Industry

Precision is paramount in the aerospace industry. Parts such as engine components and turbine blades require high levels of accuracy and repeatability, which CNC machines excel at providing. These parts are often subjected to extreme conditions, so their manufacturing needs to be flawless. CNC machines also play a crucial role in reducing the weight of parts, which is vital for performance and efficiency.

2. Automotive Industry

The automotive industry uses CNC machining for everything from engine blocks to custom parts. The ability to create parts quickly, accurately, and in large volumes makes CNC machining ideal for the high-demand nature of automotive production. Additionally, the flexibility to switch from one part to another without needing a full machine overhaul saves valuable time and resources.

3. Medical Device Manufacturing

In the medical device industry, the demand for precision is even higher. Devices like implants, surgical tools, and prosthetics require the utmost accuracy to ensure they fit and function as intended. CNC machining meets these needs, offering high precision and the ability to work with biocompatible materials.

4. Electronics Manufacturing

Electronics components, including circuit boards, connectors, and housings, often require CNC precision. Given the tiny tolerances and complex geometries involved, CNC machining is essential for ensuring components fit perfectly, contributing to the overall reliability and performance of electronic devices.

FAQs About CNC Machining

1. What is CNC in manufacturing?

CNC stands for Computer Numerical Control. In manufacturing, it refers to machines controlled by computers to automate processes like milling, turning, and drilling with high precision.

2. How does a CNC machine work?

A CNC machine works by following a set of instructions (G-code) to automate the movement of tools, allowing them to cut, shape, and finish parts with high accuracy.

3. What are the benefits of CNC machining?

The main benefits of CNC machining include high precision, faster production speeds, flexibility for various tasks, and the reduction of human error in manufacturing processes.

4. What is CNC machining used for?

CNC machining is used across industries like aerospace, automotive, medical, and electronics to manufacture parts that require extreme precision, such as engine components, implants, and circuit boards.

Conclusion: The Future of CNC Machining

In the grand scheme of manufacturing, CNC machining is not just a tool—it’s an essential technology that drives innovation, precision, and efficiency. As the world continues to demand higher quality products faster and at a lower cost, CNC technology will only continue to evolve, offering new ways to enhance production and minimize errors.

The introduction of 5-axis CNC, laser cutting, 3D printing, and smart machines points toward a future where CNC machining becomes even more integral to global manufacturing. Whether you’re a manufacturer, engineer, or business owner, investing in CNC technology means embracing the future of efficient and reliable production.