CNC Turning

V&S Engineering specializes in precision CNC turning service, leveraging advanced technology to produce high-quality cylindrical components. Our commitment to excellence ensures high accuracy and repeatability, making us a trusted partner for various industrial sectors.

CNC Turning Services for Global Industries | V&S Engineering

At V&S Engineering, we specialize in high-precision CNC turning services for a wide range of industries, including aerospace, medical, automotive, defense, and consumer products. Using state-of-the-art CNC turning machines and a skilled engineering team, we deliver consistent quality, tight tolerances, and reliable turnaround times.

We proudly support international clients across USA, Canada, Germany, and Japan, providing CNC turned components that meet global quality standards and export-ready requirements—from prototypes to high-volume production runs.

CNC Turning Services for Global Clients

V&S Engineering delivers CNC turning solutions designed to meet the expectations of international manufacturing and supply chains. Our processes focus on precision, repeatability, and compliance, making us a trusted CNC turning partner for buyers in North America, Europe, and Asia.

Whether your project demands German-level tolerances, regulatory-driven production for USA & Canada, or precision consistency expected by Japanese manufacturers, our CNC turning services are built to perform.

Why Choose V&S Engineering for CNC Turning?

When it comes to CNC turning services, you need a provider that can deliver precise, reliable, and cost-effective results. Here’s why VS Engineering should be your go-to CNC turning partner:

Precision CNC Turning

We use advanced CNC lathes and turning centers that offer exceptional precision, enabling us to achieve tolerances as tight as ±0.0001 inches.

High-Quality Materials

We work with a broad spectrum of materials, including brass, aluminum, stainless steel, titanium, and various plastics to meet the needs of your project.

Flexible Solutions

Whether you need small batch CNC turning, rapid prototypes, or large-scale production runs, we offer scalable solutions to fit your requirements.

Industry Expertise

With years of experience across industries such as aerospace, automotive, medical, and defense, we understand the specific requirements of each sector and deliver parts that meet the highest standards.

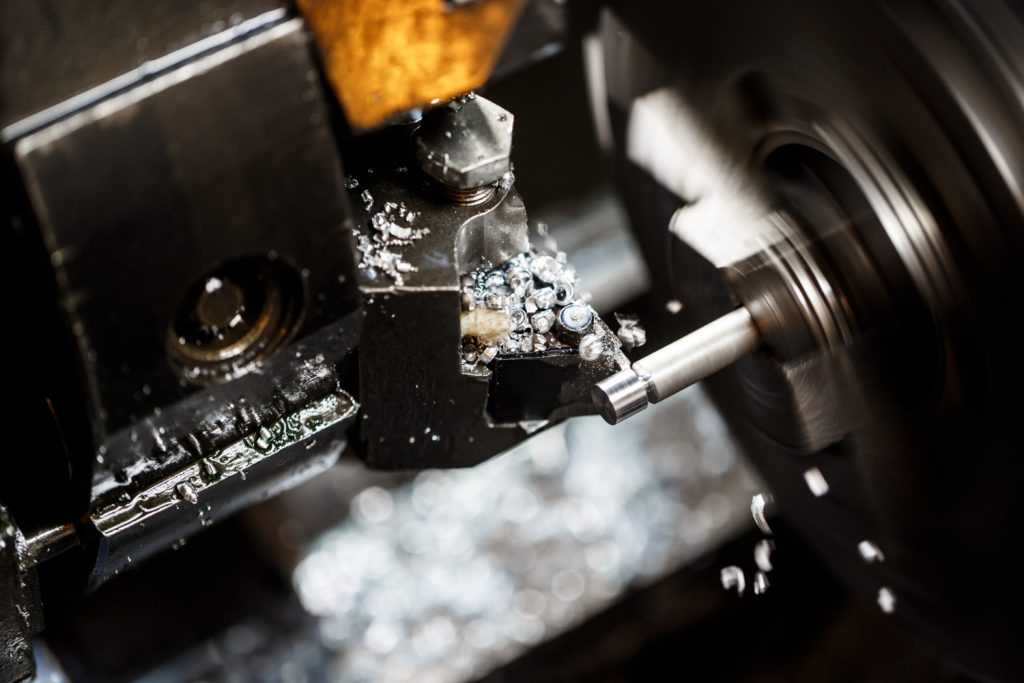

How CNC Turning Works

CNC turning is a precise manufacturing process that involves removing material from a rotating workpiece using a fixed cutting tool. The process is used to create cylindrical, spherical, or other complex shapes from various materials such as metal, plastic, or composite. Here’s how it works:

Material Loading

The raw material (e.g., aluminum, brass, or plastic) is secured in the chuck of the CNC lathe machine.

Cutting Process

As the material rotates, the CNC turning machine uses a cutting tool to shave off material in precise increments, creating the desired shape.

Operations

A range of operations can be performed, such as facing, threading, boring, grooving, knurling, and drilling, depending on your part’s design requirements.

Finishing

After the part is machined, it is typically deburred, cleaned, and may undergo additional finishing processes such as anodizing, powder coating, or polishing.

At VS Engineering, we ensure that your CNC turned parts meet exact specifications and are produced to the highest standards of quality.

CNC Turning Services We Offer

Our comprehensive CNC turning services cater to a wide range of applications and industries. Some of the specific services we offer include:

Custom CNC Turning: We produce custom, high-precision parts based on your unique specifications. Whether you need a small batch of CNC turned components or a one-off prototype, we deliver.

CNC Swiss Turning: For complex, small parts requiring high precision, our CNC Swiss turning services are the ideal solution. These machines are especially effective for parts with tight tolerances and intricate features.

CNC Vertical Turning: For larger parts, our CNC vertical turning machines provide the necessary stability and precision to ensure the highest quality.

CNC Milling and Turning: For more complex parts that require both turning and milling, we offer combined CNC turning and milling This allows us to manufacture intricate components in a single process.

CNC Turning for Prototyping: We offer fast CNC turning prototyping services to quickly produce test parts, so you can verify your designs before moving to full production.

Materials We Work With

Metals:

- Aluminum (6061-T6, 7075, 5052, etc.)

- Stainless Steel (304, 316, 17-4, 15-5, etc.)

- Brass (C360, C260)

- Titanium (Grade 2, 6Al-4V)

- Steel (1018, 4140, 4130)

- Copper (C110, C101)

Plastics:

- ABS

- Delrin (Acetal)

- Polycarbonate

- PTFE (Teflon)

- Polypropylene

- Nylon 6/6

If you don’t see the material you need, feel free to reach out to us for custom material sourcing.

Industries We Serve

Our CNC turning services are trusted by businesses across a variety of industries. Some of the industries we serve include:

Aerospace: Precision parts for aerospace components, such as engine parts, structural components, and fasteners.

Medical: CNC turned parts for medical devices, implants, and surgical tools with tight tolerances and strict quality standards.

Automotive: CNC turning services for automotive parts, including gears, brackets, and engine components.

Defense: CNC turned components for defense applications that require durability, precision, and compliance with industry standards.

Electronics & Consumer Goods: Custom CNC turned parts for electronics, appliances, and other consumer products.

Additional Services and Capabilities

- 3D CAD Design Assistance

- Secondary Operations (Anodizing, Powder Coating, Polishing)

- Custom Sourcing of Materials

- Low-Volume Production

- International Shipping & Tariff Management

Request Your CNC Turning Quote Today

Ready to get started with your CNC turning project? At V&S Engineering, we make it easy to receive a quick and accurate quote for your custom CNC turned parts. Simply upload your 3D CAD file or engineering drawing, and we’ll provide you with a competitive price and timeline for production.

Contact Us Today to learn more about our CNC turning services and how we can support your manufacturing needs.