Customization

At V&S Engineering, we understand that every project is unique. Our customization services provide tailored solutions that optimize performance, enhance efficiency, and ensure that your specific requirements are met with precision. Whether you need specialized machining, modified components, or personalized manufacturing solutions, our expertise and advanced technology make customization seamless and effective.

Customization Services

At V&S Engineering, we specialize in customization services that transform unique ideas and specific requirements into high-performance, precision-engineered solutions. We understand that no two projects are the same—standard components often fall short when performance, fit, or efficiency truly matter.

Our customized manufacturing solutions are trusted by clients across the USA, Canada, Germany, and Japan, where precision, reliability, and consistency are non-negotiable.

What Customization Means in Manufacturing

Customization in manufacturing is the process of designing, modifying, or producing components specifically to match exact functional, dimensional, and operational needs. Instead of forcing applications to fit standard products, customization ensures the product fits the application perfectly.

At V&S Engineering, customization focuses on:

- Exact dimensional accuracy

- Optimized performance

- Application-specific engineering

Seamless integration into existing systems

Why Customization Is Critical for Modern Industries

Customized components deliver clear advantages over off-the-shelf solutions:

- Precision Fit – Components engineered to your exact specifications

- Improved Efficiency – Better performance and reduced downtime

- Design Flexibility – Freedom to innovate without limitations

- Competitive Advantage – Products tailored to real-world operating conditions

Customization enables manufacturers to solve complex challenges where standard solutions fail.

Our Customization Capabilities

We provide end-to-end customization support, from concept to production.

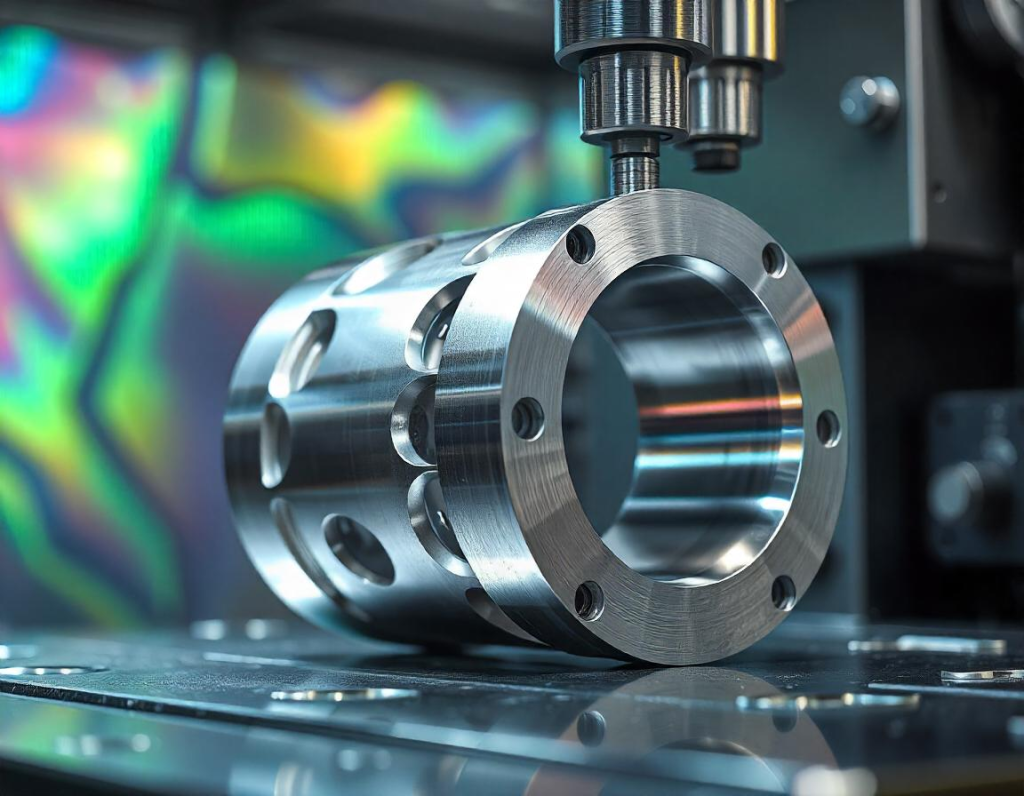

Custom Machining & Manufacturing

- CNC-based custom machining for complex geometries

- Tight tolerances and repeatable quality

- Low-volume, medium-batch, and scalable production

Prototype Development

- Rapid prototyping to validate designs

- Functional testing before full-scale production

- Design refinements based on real-world feedback

Component Modification & Optimization

- Enhancements to existing parts

- Design changes for improved durability or performance

- Adaptation to new operating environments

Custom Tooling & Fixtures

- Application-specific tools and fixtures

- Improved production accuracy and efficiency

Each project is engineered with precision, practicality, and long-term performance in mind.

Materials for Customized Manufacturing

We work with a wide range of materials to support customized applications:

- Steel & Alloy Steel – Strength and durability

- Aluminum – Lightweight and corrosion-resistant

- Titanium – High-performance applications

- Plastics & Engineering Polymers – Specialized industrial uses

Material selection is carefully aligned with functional requirements, operating conditions, and lifecycle expectations.

Industries We Support with Customization

Our customization services support a broad range of industries, including:

- Aerospace & aviation

- Medical devices & equipment

- Automotive & transportation

- Industrial machinery & manufacturing systems

Each industry benefits from our ability to meet strict tolerances, compliance requirements, and performance standards.

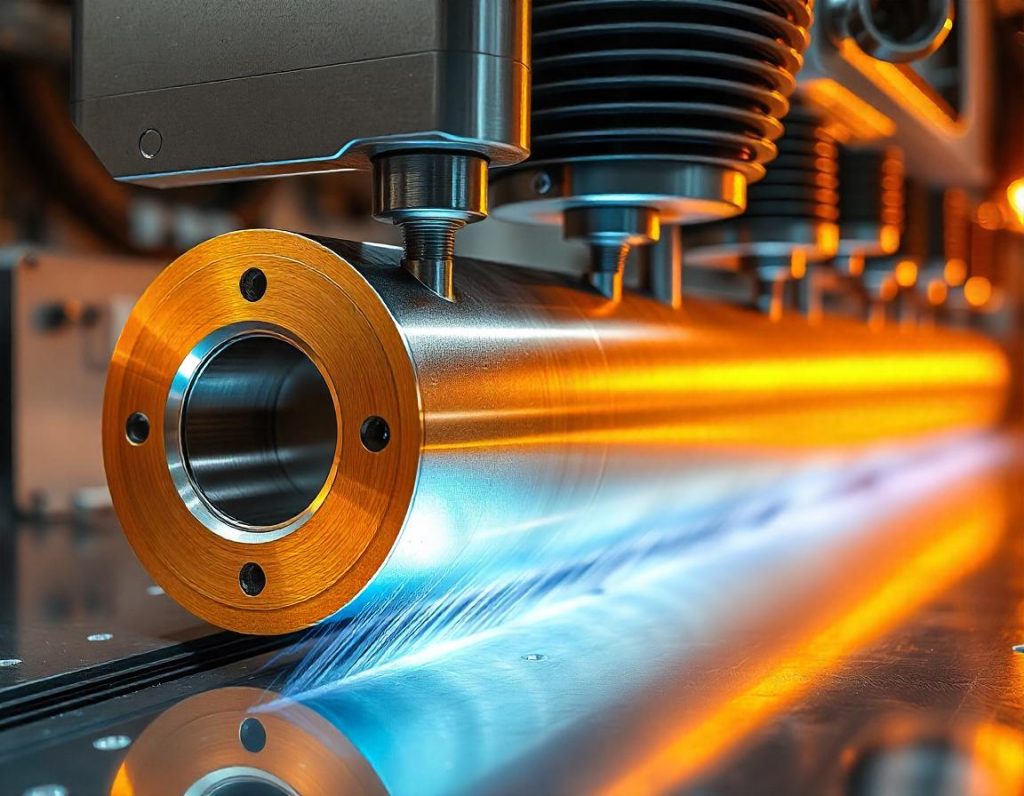

Technology-Driven Customization

We integrate advanced manufacturing technologies to deliver reliable, repeatable custom solutions:

- CAD/CAM Design & Simulation for accurate visualization

- CNC Precision Machining for detailed execution

- Process Control & Automation for consistency at scale

This technology-driven approach allows us to convert complex requirements into practical, manufacturable solutions.

Managing Challenges in Custom Manufacturing

Customization comes with unique challenges, including higher design complexity and tighter quality control. We address these through:

- Detailed upfront requirement analysis

- Optimized manufacturing planning

- Rigorous inspection and validation

This ensures cost-effective execution without compromising quality.

The Future of Custom Manufacturing

Customization is evolving with advancements in:

- AI & Machine Learning: Predictive analytics for improved manufacturing efficiency.

- Sustainable Manufacturing: Eco-friendly materials and processes.

- 3D Printing & Additive Manufacturing: Rapid prototyping and small-batch custom parts.

These innovations are shaping the future of manufacturing, making customization more accessible and cost-effective.

Why Choose V&S Engineering?

At V&S Engineering, we bring a combination of experience, technology, and dedication to every customization project. Our services offer:

- Precision-Engineered Solutions: Designed to fit your exact needs.

- Expert Team & Cutting-Edge Technology: Ensuring superior quality and efficiency.

- Flexible Manufacturing Capabilities: From prototypes to large-scale production.

Contact us today to discuss how our customized solutions can enhance your operations and meet your exact specifications.