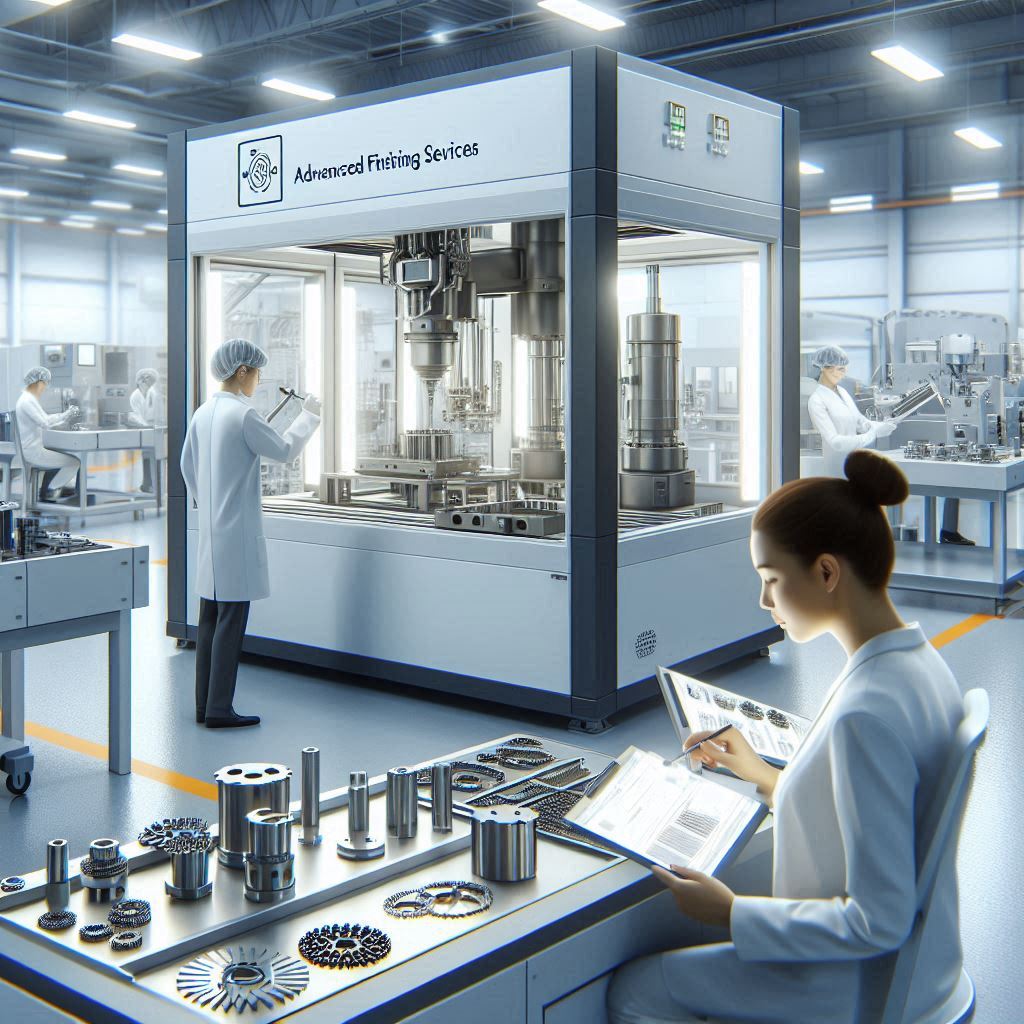

Finishing Services

At V&S Engineering, we offer professional finishing services that enhance the appearance, durability, and functionality of products across various industries. Our comprehensive solutions ensure that every component meets the highest quality standards, improving overall performance and marketability.

Finishing Services for Global Industries

At V&S Engineering, we deliver comprehensive finishing services that enhance the durability, functionality, and appearance of precision-manufactured components. Our surface finishing solutions are engineered for quality, consistency, and export-ready reliability—trusted by manufacturers serving the USA, Canada, Germany, and Japan.

From protective coatings to cosmetic surface treatments, our finishing services ensure parts perform and endure in demanding environments while meeting exact specifications.

Finishing Services Designed for Global Clients

We proudly support buyers and supply chains across:

- North America (USA & Canada)

- Europe (Germany & EU markets)

- Asia (Japan & export destinations)

Our processes adhere to internationally recognized standards and documentation practices, ensuring your finished parts are ready for assembly, international shipping, and regulatory inspection.

What Are Finishing Services?

Finishing services involve the final surface refinement and protection of parts after primary manufacturing (such as machining, welding, or fabrication).

These services aren’t just cosmetic—they:

- Improve corrosion resistance

- Enhance wear and fatigue performance

- Provide dimensional stability

- Ensure regulatory or industry compliance

- Create a consistent aesthetic quality

At V&S Engineering, we tailor finishing solutions to your part design, application, and service environment.

Types of Finishing Techniques

We offer a wide array of finishing techniques tailored to different materials and applications, including:

- Polishing: Creates smooth and reflective surfaces for an appealing look.

- Coating: Adds protective layers against rust, chemicals, and wear.

- Assembly: Puts together components for ready-to-use products.

- Labeling & Marking: Ensures effective branding and product identification.

- Surface Treatment: Enhances material properties, including hardness and resistance.

Common Applications of Finishing Services

Finishing services are crucial in:

- Automotive: Enhancing metal parts’ resistance to wear and corrosion.

- Aerospace: Ensuring aircraft components meet strict safety and durability standards.

- Electronics: Providing insulation and protection against environmental factors.

- Consumer Goods: Improving product appearance and longevity.

Materials Used in Finishing Processes

Our finishing techniques apply to multiple materials, such as:

- Metals: Aluminum, steel, brass, and titanium.

- Plastics: ABS, polycarbonate, and acrylic.

- Wood & Composites: Specialized treatments for durability and aesthetics.

Each material requires unique finishing approaches to achieve optimal results.

The Role of Quality Control

Quality control ensures:

- Industry Compliance: All products meet required specifications and standards.

- Defect Prevention: Regular inspections minimize waste and costly rework.

- Consistent Results: Each product maintains the same high level of quality.

We implement stringent quality checks at every stage of the finishing process.

Advancements in Finishing Technology

New technologies have revolutionized finishing services, enabling:

- Automated Polishing & Coating: Increasing speed and consistency.

- Computer-Aided Design (CAD): Ensuring precise finishing specifications.

- Customizable Finishing Solutions: Meeting diverse industry demands.

These advancements enhance efficiency while maintaining superior product quality.

Comparing Cost and Time Efficiency

Businesses must consider:

- Initial Investment vs. Long-Term Savings: High-end finishing techniques reduce maintenance and replacement costs.

- Production Speed: Automated processes reduce turnaround times.

- Material Costs: Choosing the right finishing technique balances affordability and performance.

Environmental Considerations in Finishing

Sustainability in finishing services includes:

- Eco-Friendly Coatings: Reducing harmful chemical usage.

- Waste Reduction Techniques: Minimizing material waste in production.

- Energy-Efficient Processes: Implementing greener technologies to lower environmental impact.

We are committed to adopting environmentally responsible finishing solutions.

Choosing the Right Finishing Service

Selecting the right finishing service involves:

- Understanding Project Requirements: Material type, finish expectations, and industry regulations.

- Partnering with Experts: Ensuring access to tailored solutions and advanced techniques.

- Balancing Cost & Quality: Investing in the right finishing method for optimal performance and longevity.

Why Choose V&S Engineering?

At V&S Engineering, we provide industry-leading finishing services that meet your project needs with precision and efficiency.

Contact us today to discuss your finishing requirements and discover how we can enhance your product’s quality and performance.