Metal Coating

At V&S Engineering, we specialize in high-quality metal coating solutions designed to enhance durability, corrosion resistance, and aesthetic appeal. Our advanced coating processes ensure long-lasting protection for metal surfaces across various industries.

Professional Metal Coating Services

At V&S Engineering, we deliver advanced metal coating services designed to enhance the durability, corrosion resistance, wear performance, and aesthetic quality of metal components. Serving clients across the USA, Canada, Germany, and Japan, we provide industrial metal coating solutions tailored to meet the demanding requirements of automotive, aerospace, oil & gas, and manufacturing industries.

Our expertise in metal surface coating, protective metal coating, and custom metal coating solutions ensures long-lasting protection even in the harshest operating environments. Whether you need corrosion-resistant metal coating, heat-resistant metal coating, or wear-resistant metal coating, we deliver precision-engineered results that improve product lifespan, reliability, and performance.

What Is Metal Coating and Why Does It Matter?

Metal coating is the application of a specialized protective layer onto a metal substrate to prevent corrosion, reduce friction, improve wear resistance, and enhance surface durability. Industries rely on metal finishing and coating to protect critical components exposed to moisture, chemicals, extreme temperatures, and mechanical stress.

Our metal coating solutions create a robust barrier against environmental degradation while maintaining structural integrity and performance efficiency.

Key Benefits of Our Metal Coating Services:

- Superior corrosion protection

- Enhanced wear and abrasion resistance

- Improved heat resistance

- Increased component lifespan

- Reduced maintenance and replacement costs

Enhanced aesthetic and surface finish

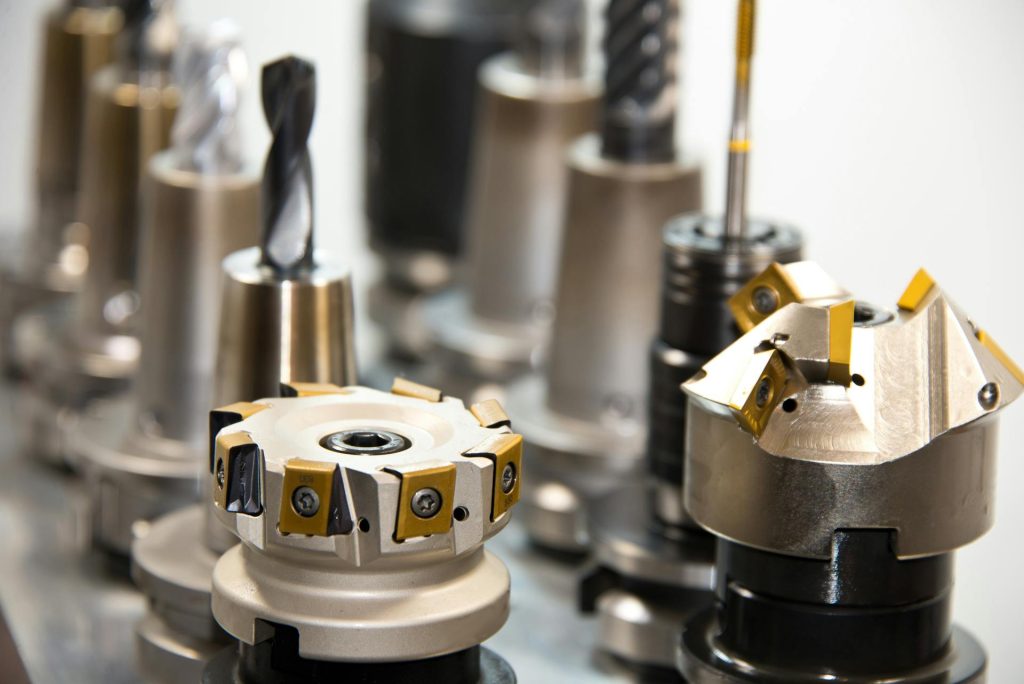

Advanced Metal Coating Technologies We Offer

We utilize cutting-edge coating technologies to provide industry-leading results:

- Powder Coating Services

A durable, eco-friendly coating that delivers excellent resistance to corrosion, chipping, and fading—ideal for industrial machinery and structural components. - Thermal Spray Coating

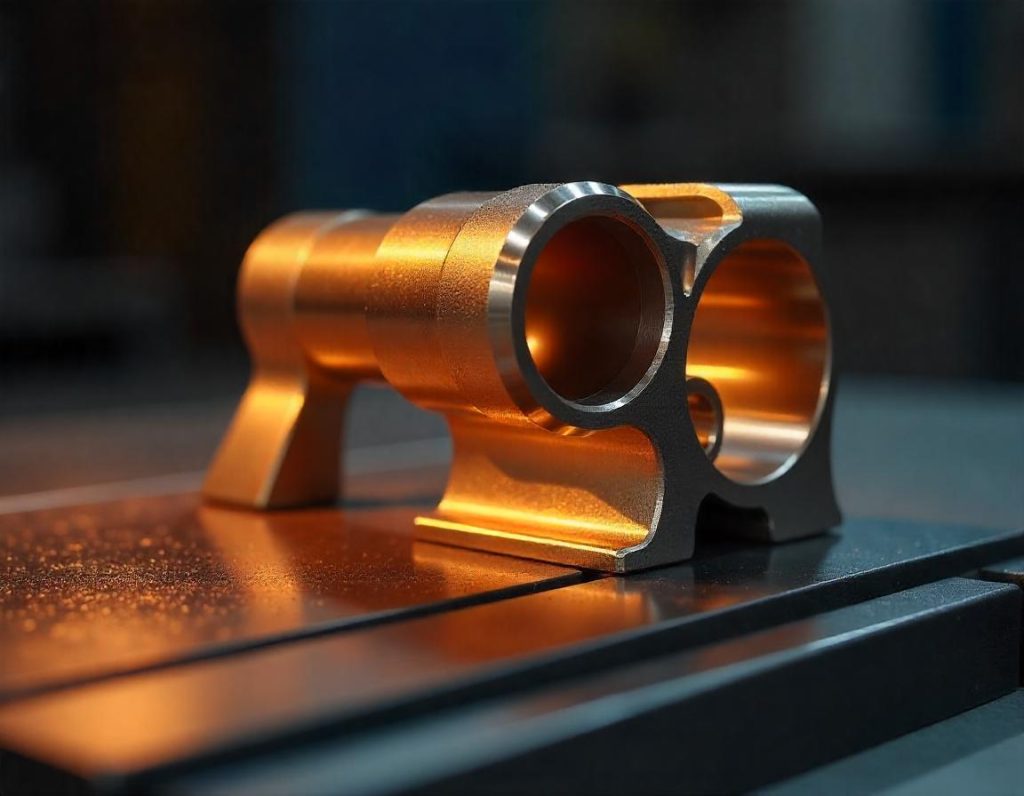

Used for high-temperature and wear-prone applications, offering exceptional durability for aerospace and heavy industrial components. - PVD Coating Services (Physical Vapor Deposition)

Provides ultra-thin, high-performance coatings that enhance hardness, reduce friction, and improve chemical resistance. - Electroplating Services

Applies metallic layers such as nickel, chrome, or zinc to improve corrosion resistance, conductivity, and surface finish. - Anodizing Metal Coating

Specifically for aluminum, improving surface hardness, corrosion resistance, and aesthetic appeal. - Ceramic Metal Coating

Ideal for extreme heat and chemical exposure, commonly used in aerospace and industrial applications. - Zinc Coating Services & Nickel Coating Services

Highly effective for anti-corrosion coating for metals, especially in marine, automotive, and infrastructure sectors. - Chrome Plating Services

Provides superior surface hardness, corrosion resistance, and aesthetic appeal for precision components

Industry Applications of Our Metal Coating Services

Automotive Industry

We provide:

- Metal coating for automotive parts

- Automotive metal coating services

- Corrosion protection for car components

Our coatings extend vehicle lifespan, improve performance, and enhance durability in harsh driving conditions.

Aerospace Industry

We specialize in:

- Aerospace metal coating

- High-temperature metal coating for aircraft

- Aerospace protective coatings

Our coatings meet stringent aviation standards for safety, performance, and longevity.

Oil & Gas Industry

We support:

- Metal coating for oil and gas equipment

- Corrosion-resistant coating for pipelines

- Industrial coating for oil rigs

Designed to withstand extreme corrosion, chemical exposure, and high pressure.

Manufacturing & Engineering

We provide:

- Metal coating for industrial machinery

- Protective coating for heavy equipment

- Metal finishing for precision parts

Our solutions improve operational efficiency and reduce downtime due to component failure.

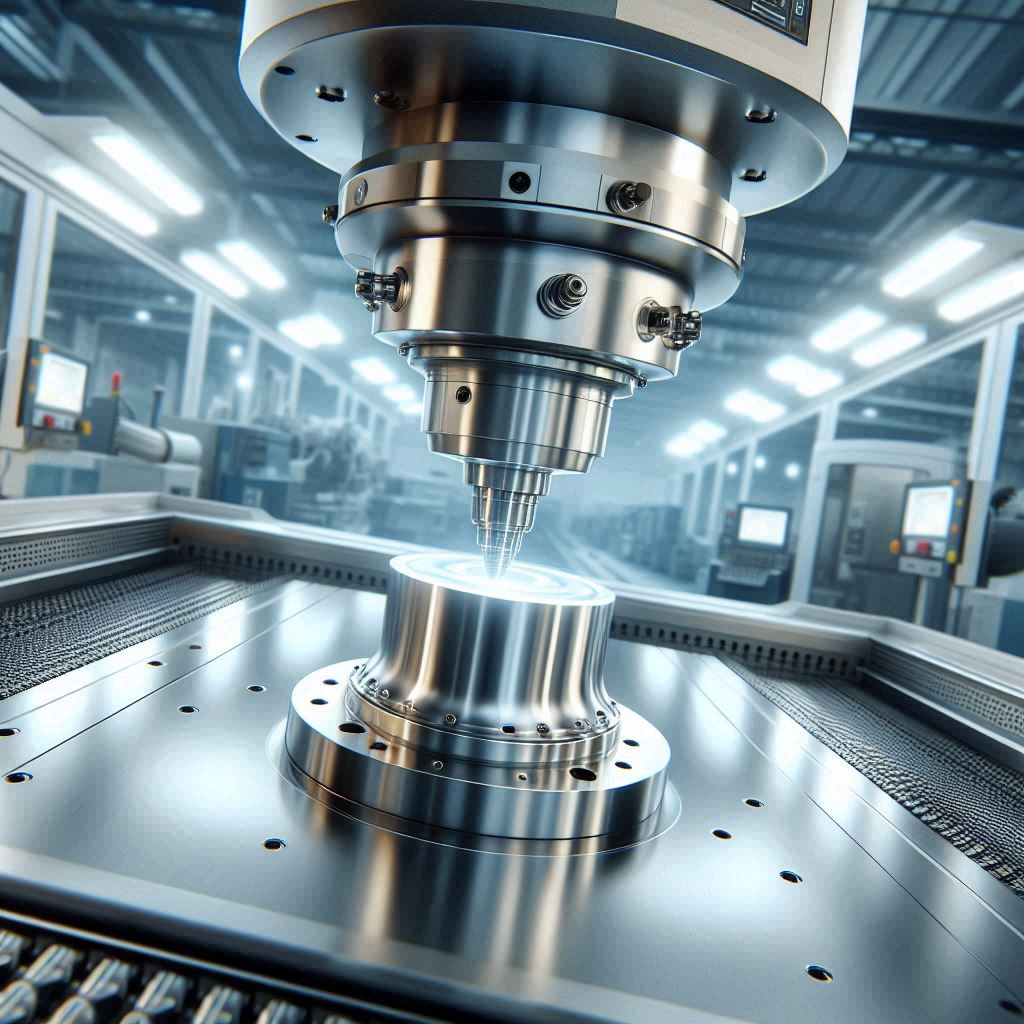

Our Precision Metal Coating Process

We follow a controlled, multi-stage process to ensure flawless coating application:

Surface Preparation

- Thorough cleaning and degreasing

- Removal of contaminants

- Surface etching to enhance adhesion

Coating Application

- Selection of optimal coating method based on material and use-case

- Precision-controlled application for uniform coverage

Curing & Drying

- Temperature-controlled curing for maximum bonding strength

Quality Control & Inspection

- Thickness measurement

- Adhesion testing

- Corrosion and wear resistance validation

Our rigorous quality control ensures compliance with ISO and ASTM standards.

Standard Practices for Metal Coating

Adhering to industry standards ensures consistent quality and performance. Best practices include:

- Precise Measurement of Coating Thickness: Prevents undercoating or overcoating issues.

- Controlled Application Methods: Reduces waste and ensures uniform coverage.

- Comprehensive Testing & Inspection: Guarantees compliance with industry regulations.

Following these protocols results in high-performance coatings with maximum durability.

Compliance and Regulations in Metal Coating

The metal coating industry is regulated to ensure environmental sustainability and safety. Key considerations include:

- Environmental Impact: Use of non-toxic, eco-friendly coatings.

- Industry Certifications: Compliance with ISO, ASTM, and other regulatory standards.

- Safety Protocols: Protecting workers from hazardous materials and fumes.

Meeting these regulations ensures responsible and high-quality coating applications.

Evaluating Durability and Longevity

Durability assessments help determine coating lifespan and effectiveness. These tests include:

- Corrosion Resistance Testing: Simulating harsh environmental conditions.

- Adhesion Testing: Ensuring coatings stay bonded to the substrate over time.

- Wear & Abrasion Testing: Measuring resistance to physical damage and friction.

These evaluations guide improvements in coating formulations and application techniques.

Cost Factors in Metal Coating

Metal coating costs depend on several factors:

- Type of Coating: Some materials and processes are more expensive than others.

- Surface Preparation Requirements: Extensive cleaning and pre-treatment may increase costs.

- Coating Thickness & Coverage Area: More material usage leads to higher expenses.

- Long-Term Savings: Investing in durable coatings reduces maintenance and replacement costs.

Balancing cost with performance is crucial when selecting a coating solution.

Case Studies on Successful Metal Coating Applications

Metal coatings play a vital role in various industries:

- Automotive: Corrosion-resistant coatings extend vehicle lifespan and maintain appearance.

- Construction: Protective coatings safeguard structural steel from harsh weather conditions.

- Manufacturing: Coatings enhance the durability of machinery and industrial equipment.

Real-world applications demonstrate the importance of metal coating in ensuring product reliability and longevity.

Why Choose V&S Engineering for Metal Coating?

We are a trusted metal coating service provider and industrial metal coating contractor with a global reputation for excellence.

Why Industrial Clients Choose Us:

- Cutting-edge coating technologies

- Custom metal coating solutions for large industries

- Industry-certified processes

- High-performance metal coatings

- Reliable supply chain and fast turnaround

- Expertise in multi-industry applications

We are a preferred metal coating company in the United States, Canada, Germany, and Japan, serving manufacturers, engineers, and global buyers seeking premium coating solutions.

If you’re ready to hire a metal coating company or need a metal coating quote, contact V&S Engineering today.

Contact Us Today to discuss your project and discover how our metal coating services can enhance your product performance and longevity.