Production Machining

At V&S Engineering, we provide high-quality production machining services that optimize efficiency, precision, and cost-effectiveness. Our state-of-the-art machining processes ensure superior component manufacturing for industries such as aerospace, automotive, and industrial equipment.

Production Machining Services

At V&S Engineering, we deliver Production Machining Services designed for accuracy, consistency, and cost efficiency. Using advanced CNC technology and strict quality control, we manufacture precision components that meet the demanding standards of aerospace, automotive, industrial equipment, and export-driven industries.

We support clients across the USA, Canada, Germany, and Japan, providing machining solutions that scale reliably from low-volume batches to high-volume production runs.

What Is Production Machining?

Production machining is the industrial process of manufacturing precision components in repeatable quantities using controlled material removal techniques. Unlike prototype machining, production machining focuses on process stability, tight tolerances, and long-term consistency.

At V&S Engineering, production machining is engineered to:

- Maintain uniform quality across every part

- Reduce unit cost at scale

Meet international dimensional and surface finish standards

Types of Production Machining Processes

We offer a full range of CNC-based production machining processes, optimized for complex geometries and demanding applications.

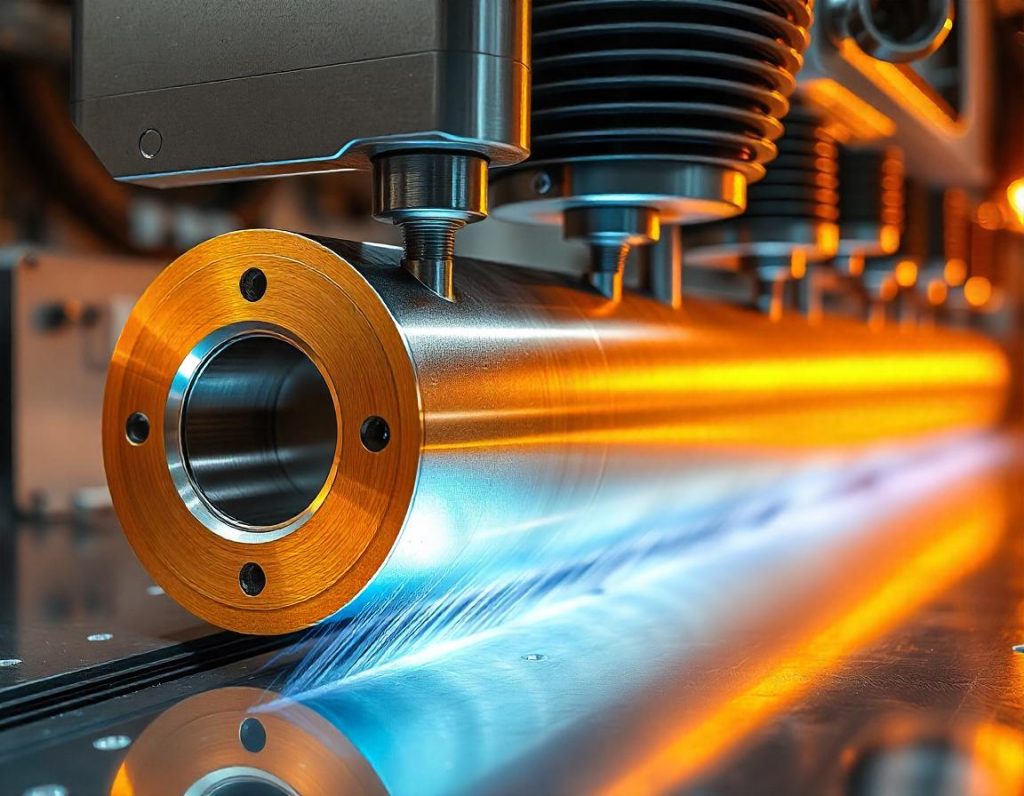

CNC Turning

- Ideal for cylindrical and rotational components

- High repeatability for large production volumes

- Tight concentricity and dimensional accuracy

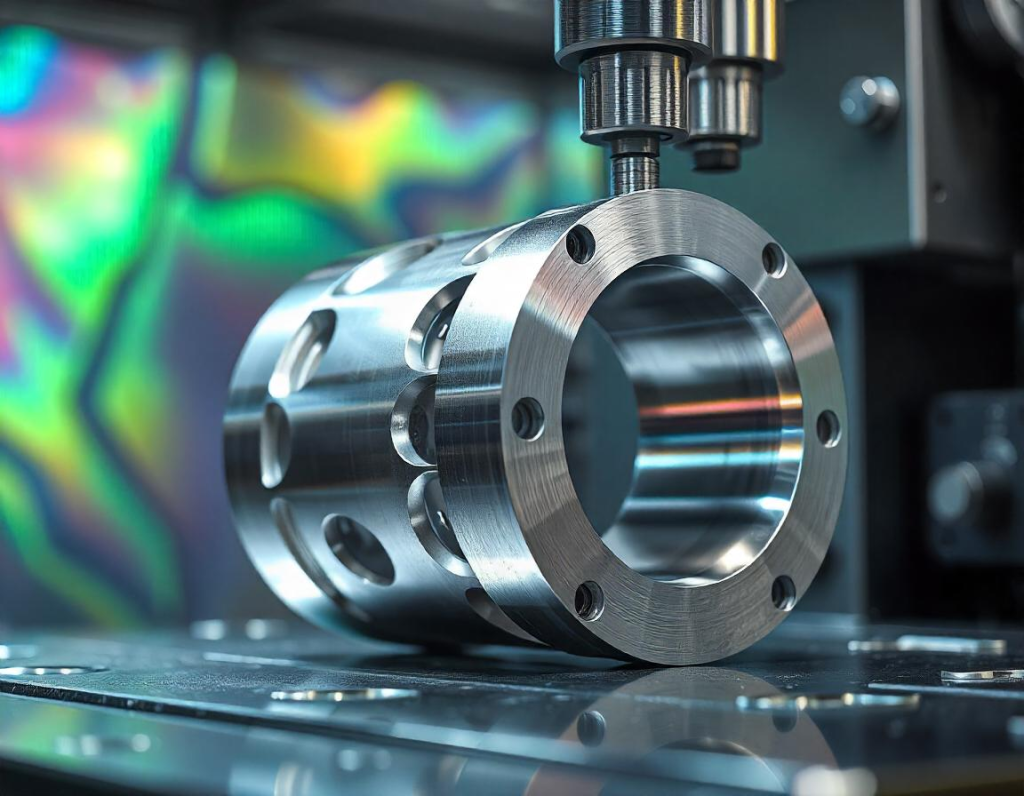

CNC Milling

- Precision machining of flat surfaces, pockets, slots, and complex profiles

- Multi-axis capability for intricate parts

- Suitable for structural and functional components

Drilling & Hole Making

- Accurate hole placement and depth control

- Threading and tapping for assembly-ready parts

Grinding & Finishing

- Ultra-fine surface finishes

- Precision tolerance control for critical components

Choosing the correct machining process ensures performance, durability, and cost optimization.

Key Materials Used in Production Machining

The materials used in machining impact the efficiency and durability of the final product. Common materials include:

- Steel: Known for its strength and versatility.

- Aluminum: Lightweight and easy to machine.

- Titanium: Preferred for aerospace applications due to its strength-to-weight ratio.

- Plastics & Composites: Increasingly used in modern engineering for specialized applications.

Selecting the right material is essential for performance, longevity, and cost-effectiveness.

Importance of Precision in Machining

Precision machining ensures:

- Tight Tolerances: Reducing variability and defects in components.

- Enhanced Product Performance: Ensuring exact fits and reliable operation.

- Minimized Waste: Lowering material costs through accuracy and efficiency.

Maintaining high precision improves overall manufacturing success and customer satisfaction.

Advancements in Machining Technology

Technological advancements have dramatically improved machining capabilities. Innovations include:

- CNC Automation: High repeatability and reduced human error.

- IoT Monitoring: Real-time process tracking and predictive maintenance.

- Advanced CAD/CAM Software: Streamlined design-to-production workflow.

These improvements enhance efficiency, precision, and scalability in manufacturing.

Quality Control Methods in Production Machining

Ensuring quality in production machining involves:

- Statistical Process Control (SPC): Monitoring production consistency.

- In-Process Inspections: Detecting defects early to minimize waste.

- Surface Finish Analysis: Ensuring components meet required specifications.

Implementing rigorous quality checks leads to superior product reliability and compliance with industry standards.

Safety Practices in Machining Environments

Safety is critical in machining operations. Best practices include:

- Equipment Maintenance: Regular servicing to prevent failures.

- Operator Training: Ensuring personnel understand machine safety protocols.

- Use of Personal Protective Equipment (PPE): Helmets, gloves, and protective eyewear.

- Workplace Organization: Keeping areas clean to reduce hazards.

A commitment to safety enhances productivity and minimizes risks.

Industries We Support

The future of machining includes:

- Increased Automation & AI Integration: Reducing costs and improving consistency.

- Eco-Friendly Manufacturing Practices: Minimizing waste and improving sustainability.

- Enhanced Smart Factories: Data-driven efficiency improvements.

By staying ahead of technological advancements, manufacturers can remain competitive in a rapidly evolving industry.

Future-Ready Production Machining

We align our machining capabilities with evolving industry demands by focusing on:

- Higher automation and process intelligence

- Sustainable machining practices

- Continuous improvement in cycle time and efficiency

This ensures our clients remain competitive in fast-moving global markets.

Why Choose V&S Engineering?

Optimizing production machining efficiency is essential for maintaining competitiveness in today’s manufacturing landscape. By embracing:

- Cutting-Edge Technologies to enhance precision and output.

- Strict Quality Control Measures to ensure high standards.

- Safe and Sustainable Practices to protect workers and the environment.

V&S Engineering is dedicated to delivering state-of-the-art production machining services. Contact us today to learn how we can support your manufacturing needs with precision and expertise.