What Is PLA?

What is PLA? Learn about PLA material properties, uses, biodegradability, packaging applications, and how to buy PLA resin from trusted suppliers worldwide.

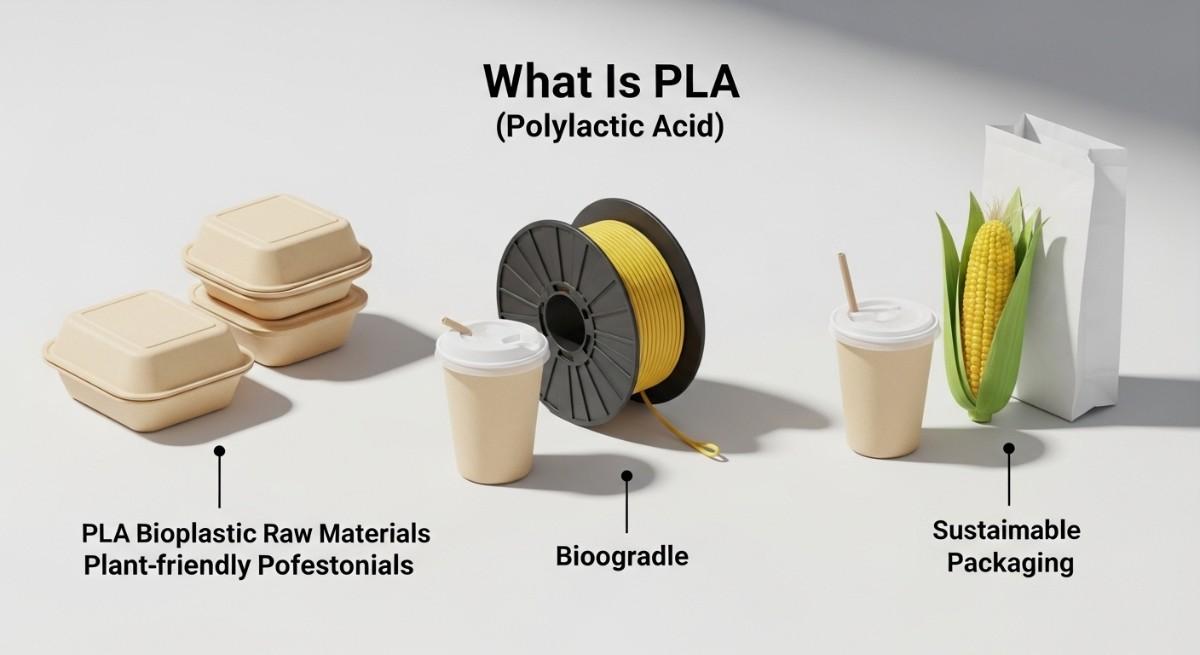

As global industries shift toward sustainability, PLA (Polylactic Acid) has emerged as one of the most important biodegradable and bio-based plastics in modern manufacturing. From eco-friendly packaging to 3D printing filaments and medical devices, PLA plastic is redefining how businesses reduce environmental impact without sacrificing performance.

This guide explains what PLA plastic is, how it’s made, its material properties, advantages, disadvantages, and applications, and why manufacturers across the USA, Canada, Germany, and Japan are increasingly choosing PLA for commercial and industrial use.

Polylactic Acid

PLA (Polylactic Acid) is a bioplastic polymer made from renewable plant-based raw materials such as corn starch, sugarcane, or cassava. Unlike conventional plastics derived from petroleum, PLA is produced using fermented plant sugars, making it a leading solution in the biodegradable plastic PLA material category.

PLA is widely known as:

PLA bioplastic

PLA polymer material

PLA biodegradable plastic

PLA resin for packaging and molding

It offers a strong balance of mechanical performance, processability, and sustainability, making it suitable for both consumer and industrial markets.

How Is PLA Plastic Made?

Understanding PLA plastic manufacturing helps buyers evaluate quality and sourcing.

PLA Manufacturing Process (Simplified)

Fermentation – Plant sugars are fermented to produce lactic acid

Polymerization – Lactic acid is converted into PLA polymer resin

Pelletizing – PLA is processed into PLA granules or pellets

Manufacturing Use – Pellets are used for injection molding, extrusion, thermoforming, or 3D printing

This process significantly reduces carbon emissions and fossil fuel dependence, making PLA an eco-friendly plastic alternative.

PLA Material Properties

Key PLA material properties include:

| Property | Typical Value |

|---|---|

| Density | ~1.24 g/cm³ |

| Tensile Strength | ~50 MPa |

| Glass Transition Temperature | ~60°C |

| Melting Temperature | 130–180°C |

| Appearance | Transparent to opaque |

| Origin | Renewable plant-based |

PLA offers good rigidity, surface finish, and dimensional accuracy, especially compared to traditional plastics.

PLA Plastic Uses & Applications

1. PLA Plastic for Packaging

PLA is widely used as a sustainable packaging material, including:

PLA food containers

Compostable cups and cutlery

PLA films and trays

PLA blister packaging

Many brands use PLA packaging material to meet sustainability regulations in Germany, Canada, and Japan.

2. PLA Material for 3D Printing

PLA filament material is one of the most popular choices in additive manufacturing due to:

Low printing temperature

Minimal warping

Smooth surface finish

Low odor and emissions

Ideal for prototyping, consumer products, and educational use.

3. PLA Resin Applications in Manufacturing

PLA resin is used for:

Injection molding

Thermoforming

Extrusion

Fiber and textile production

Manufacturers frequently source PLA resin for injection molding from industrial PLA material suppliers.

4. Medical & Consumer Applications

PLA is also used in:

Biodegradable medical implants

Surgical sutures

Disposable hygiene products

Consumer electronics housings

Is PLA Plastic Biodegradable & Compostable?

One of the most common questions is:

Is PLA plastic biodegradable?

Yes — PLA is a biodegradable material, but under specific conditions.

Industrially compostable (high heat, humidity, microbial activity)

Not designed to degrade quickly in landfills or oceans

Meets many compostable plastic standards globally

How Long Does PLA Take to Degrade?

Industrial composting: 3–6 months

Landfill or natural environment: Several years

This makes PLA ideal for controlled waste systems and sustainable packaging programs.

PLA Plastic Advantages and Disadvantages

Advantages of PLA Plastic

Made from renewable resources

Lower carbon footprint

Food-contact safe (grades available)

Excellent clarity and appearance

Easy to process for manufacturers

Popular for eco-friendly branding

Disadvantages of PLA Plastic

Lower heat resistance than ABS or PET

Requires industrial composting

Can be brittle without modification

PLA Plastic vs ABS: Which Is Better?

| Feature | PLA | ABS |

|---|---|---|

| Source | Renewable | Petroleum-based |

| Biodegradable | Yes (industrial) | No |

| Heat Resistance | Lower | Higher |

| Environmental Impact | Low | High |

| Ease of Processing | Easier | Moderate |

PLA plastic vs ABS decisions often depend on heat resistance vs sustainability requirements.

Is PLA Plastic Safe for Food Packaging?

Yes. PLA plastic food packaging material is widely used for:

Cold food containers

Beverage cups

Disposable utensils

Food-grade PLA complies with FDA and EU food-contact regulations when sourced from certified suppliers.

Global Market Demand for PLA Plastic

Businesses worldwide are sourcing PLA from:

PLA plastic suppliers USA

PLA material manufacturers in Canada

PLA polymer suppliers in Germany

PLA plastic exporters in Japan

Industries driving demand include:

Sustainable packaging

Food service

Consumer goods

Medical devices

Automotive interiors

How to Buy PLA Plastic Resin or Granules

When sourcing PLA, look for:

Certified PLA raw material manufacturers

Food-grade or industrial-grade options

Bulk PLA plastic material availability

Reliable global logistics

Many companies actively search for:

PLA plastic suppliers

PLA granules suppliers

Buy PLA plastic resin in the USA

Industrial PLA polymer manufacturers

FAQs

Is PLA plastic recyclable?

PLA can be chemically or mechanically recycled, but it requires dedicated recycling streams.

Is PLA better than plastic?

PLA is more sustainable than petroleum plastics, but is not suitable for all high-heat applications.

What is PLA plastic used for?

Packaging, 3D printing, medical devices, textiles, and consumer products.

Is PLA compostable?

Yes, PLA compostable plastic requires industrial composting conditions.

What are the disadvantages of PLA?

Low heat resistance and limited degradation in natural environments.

Conclusion: Why PLA Plastic Is the Future of Sustainable Manufacturing

PLA (Polylactic Acid) has become one of the most important biodegradable and sustainable plastic materials in the global market. Its versatility, renewable origin, and growing regulatory support make it a strong choice for manufacturers, packaging companies, and industrial buyers.

As demand increases across North America, Europe, and Asia, businesses that adopt PLA polymer material gain a competitive edge in sustainability and compliance.