What Is Polypropylene?

What is polypropylene? Learn about polypropylene properties, uses, manufacturing process, advantages, and industrial applications of PP plastic.

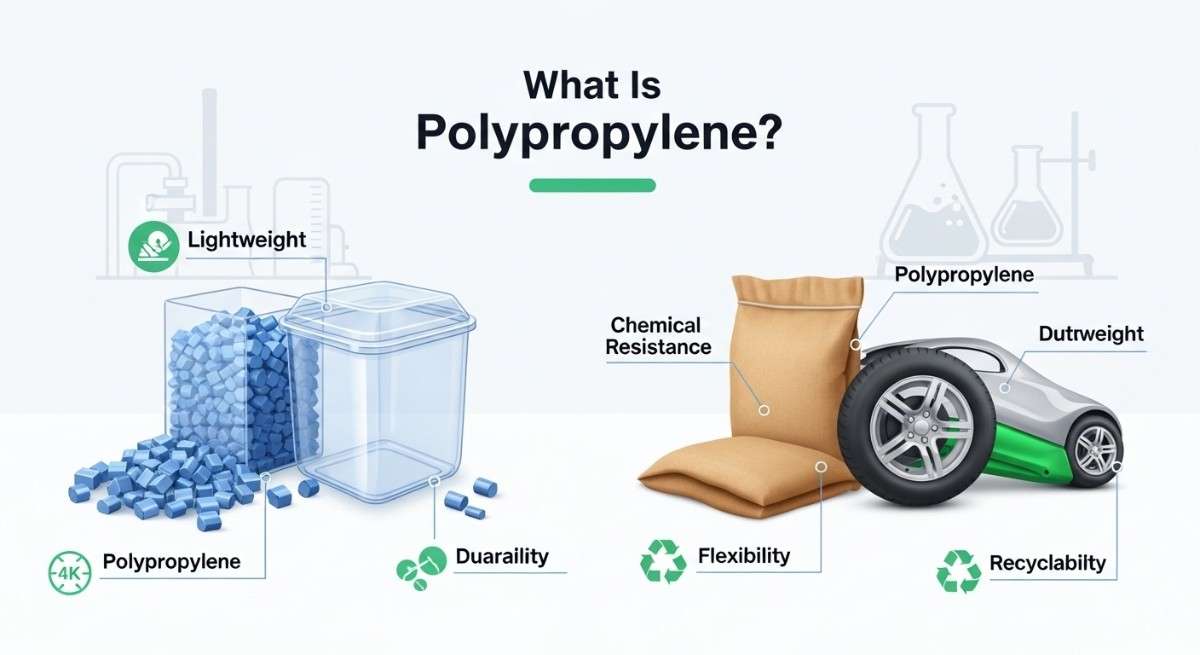

Polypropylene is one of the most widely used thermoplastic polymers in the world, playing a critical role across packaging, automotive, medical, construction, and consumer goods industries. Known for its durability, chemical resistance, and cost efficiency, polypropylene plastic has become a preferred material for manufacturers and industrial buyers seeking performance and scalability.

In this guide, we’ll explore what polypropylene is, its material properties, manufacturing process, industrial uses, and advantages and disadvantages, helping buyers and engineers make informed sourcing and material-selection decisions.

Polypropylene

Polypropylene (PP) is a thermoplastic polymer derived from petroleum-based propylene monomers. It belongs to the polyolefin family and is recognized for its lightweight structure, high fatigue resistance, and versatility in industrial applications.

Key Characteristics of Polypropylene Material

Semi-crystalline thermoplastic polymer

Low density with high strength-to-weight ratio

Excellent resistance to chemicals, acids, and alkalis

Suitable for injection molding, extrusion, and thermoforming

Because of these properties, PP plastic is widely used in both consumer and heavy-duty industrial products.

Polypropylene Chemical Structure and Polymer Types

Polypropylene is produced by polymerizing propylene gas using catalysts. Its molecular structure determines its performance characteristics.

Types of Polypropylene Polymer

Homopolymer Polypropylene

High stiffness and tensile strength

Common in packaging, textiles, and consumer products

Copolymer Polypropylene

Improved impact resistance and flexibility

Used in automotive polypropylene plastic and industrial containers

Polypropylene Material Properties

Understanding polypropylene material properties is essential for selecting the right grade for industrial or commercial use.

Mechanical Properties

High fatigue resistance (excellent for hinges and caps)

Good tensile strength

Low coefficient of friction

Thermal Properties

Polypropylene melting point: ~160–170°C (320–338°F)

Maintains performance in high-temperature environments

Suitable for hot-fill and heat-resistant packaging

Physical Properties

Polypropylene density: ~0.90 g/cm³ (lighter than most plastics)

Moisture resistant

Electrically insulating

Chemical Resistance

Resistant to solvents, acids, and bases

Ideal for chemical containers and industrial tanks

How Polypropylene Is Manufactured

The polypropylene manufacturing process involves advanced polymerization techniques to ensure consistency and performance.

Manufacturing Steps

Propylene extraction from petroleum or natural gas

Polymerization using Ziegler-Natta or metallocene catalysts

Pelletizing into polypropylene pellets or resin

Processing through injection molding or extrusion

Common Industrial Processing Methods

Injection molding polypropylene

Extrusion-grade polypropylene

Blow molding and thermoforming

Polypropylene Plastic Uses Across Industries

Industrial Polypropylene Applications

Polypropylene’s versatility makes it ideal for large-scale manufacturing and industrial use.

Packaging Industry

Polypropylene packaging material

Food grade polypropylene containers

Caps, closures, films, and trays

Automotive Industry

Automotive polypropylene plastic components

Dashboards, bumpers, battery cases

Lightweight parts for fuel efficiency

Medical & Healthcare

Medical-grade polypropylene syringes

Laboratory equipment

Sterile packaging

Construction & Infrastructure

Pipes and fittings

Geotextiles

Insulation materials

Consumer & Industrial Goods

Storage containers

Industrial polypropylene products

Fibers and woven fabrics

Polypropylene Advantages and Disadvantages

Advantages of Polypropylene Material

Lightweight and cost-effective

Excellent chemical resistance

High fatigue strength

Food-safe and medical-grade options available

Easily recyclable

Disadvantages of Polypropylene

Lower UV resistance without additives

Brittle at extremely low temperatures

Limited adhesion with paints or adhesives

Understanding these trade-offs helps buyers choose the right polypropylene resin or pellets for their application.

Polypropylene vs Other Plastics

Polypropylene vs Polyethylene

Polypropylene is stiffer and more heat-resistant

Polyethylene offers better impact resistance at low temperatures

Polypropylene vs PVC

Polypropylene is lighter and more chemically resistant

PVC offers better rigidity but contains plasticizers

Is Polypropylene Safe and Recyclable?

Is polypropylene safe?

Yes. Food-grade and medical-grade polypropylene are approved for direct contact with food and pharmaceuticals.Is polypropylene recyclable?

Yes. PP plastic is recyclable (Resin Identification Code #5) and widely accepted in industrial recycling streams.

Frequently Asked Questions (FAQ)

What is polypropylene plastic used for?

Polypropylene is used in packaging, automotive parts, medical devices, textiles, construction materials, and industrial containers.

Why is polypropylene used in packaging?

Its lightweight nature, chemical resistance, food safety, and durability make it ideal for food and industrial packaging.

What are the key benefits of polypropylene material?

High strength-to-weight ratio, chemical resistance, recyclability, and cost efficiency.

What is the melting point of polypropylene?

The polypropylene melting point ranges from 160°C to 170°C.

Is polypropylene suitable for industrial use?

Yes. Industrial polypropylene is widely used due to its mechanical strength, thermal stability, and processing flexibility.

How is polypropylene manufactured?

It is produced through the polymerization of propylene gas and processed into resin, pellets, or finished components.

Conclusion

Polypropylene is a high-performance, cost-efficient, and versatile polymer that supports a wide range of industrial and commercial applications. Its durability, thermal stability, and chemical resistance make it a preferred material for manufacturers, engineers, and procurement teams worldwide.

For businesses seeking reliable polypropylene suppliers, bulk polypropylene material, or custom industrial polypropylene products, PP plastic remains a future-ready solution aligned with sustainability and performance demands.