What is TPU material?

What is TPU material? Learn the meaning, properties, advantages, disadvantages, uses, and comparisons of Thermoplastic Polyurethane (TPU) for industrial and commercial applications.

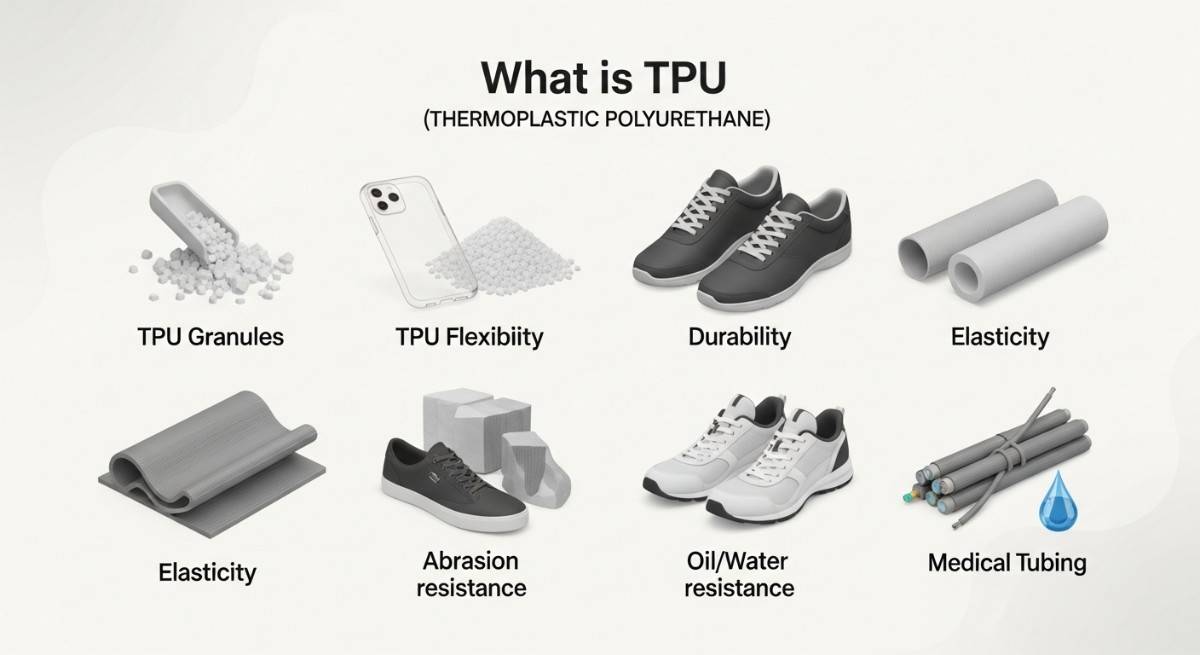

TPU material, also known as Thermoplastic Polyurethane, is one of the most versatile and high-performance polymers used in modern manufacturing. It is widely adopted across industries such as automotive, electronics, medical devices, footwear, sportswear, cables, and industrial equipment due to its exceptional balance of flexibility, strength, durability, and chemical resistance.

As global manufacturers increasingly demand materials that can withstand mechanical stress, environmental exposure, and long service life, TPU plastic has emerged as a preferred alternative to traditional rubber, PVC, and other flexible plastics.

This guide explains what TPU material is, its properties, benefits, limitations, applications, processing methods, and how it compares to other materials—helping buyers and decision-makers choose the right material for their products.

TPU Material

TPU Meaning and TPU Full Form

TPU stands for Thermoplastic Polyurethane. It is a type of thermoplastic elastomer (TPE) that combines:

The elasticity and softness of rubber

The strength, durability, and processability of plastic

Unlike traditional rubber, TPU can be melted, reshaped, and recycled without losing performance, making it highly efficient for industrial production.

What Is Thermoplastic Polyurethane (TPU)?

Thermoplastic Polyurethane is a polyurethane-based polymer formed by reacting diisocyanates with polyols and chain extenders. This creates a segmented molecular structure consisting of:

Soft segments – provide flexibility and elasticity

Hard segments – deliver mechanical strength and abrasion resistance

This structure allows the TPU polymer to perform reliably under repeated stress, impact, bending, and exposure to chemicals.

TPU Material Properties Explained

Key Characteristics of TPU Plastic

TPU material properties make it suitable for both demanding industrial environments and consumer-facing products.

Mechanical Properties

Highly flexible plastic with rubber-like elasticity

Excellent abrasion-resistant material

Strong impact resistance

High wear resistance

Good tensile, tear, and fatigue strength

Chemical and Environmental Properties

Chemical-resistant plastic (oils, fuels, greases, solvents)

Moderate heat-resistant polymer (typically -40°C to 120°C)

Resistant to UV, ozone, and weathering (formulation dependent)

Certain grades offer hydrolysis and microbial resistance

Physical Properties

Available in soft TPU and hard TPU

Can be transparent TPU or colored TPU

Lightweight yet extremely durable

Smooth, high-quality surface finish

Is TPU a Good Material?

Yes. TPU is considered a premium engineering material for applications requiring durability, flexibility, and long-term performance.

Benefits of TPU Material

Combines rubber-like flexibility with plastic strength

Long service life under mechanical stress

Excellent resistance to abrasion and impact

Wide hardness range for design flexibility

Recyclable and reprocessable

Suitable for complex shapes and precision parts

TPU Material Disadvantages

Higher cost compared to PVC or basic plastics

Lower heat resistance than silicone

Requires controlled processing conditions

TPU Uses and Applications Across Industries

TPU Applications by Industry

Consumer Electronics

TPU in phone cases

Protective covers and housings

Flexible connectors and seals

Footwear and Sportswear

TPU in footwear soles and midsoles

TPU in sportswear logos and flexible components

High-performance films and laminates

Automotive Industry

TPU in automotive parts

Wire and cable jacketing

Air ducts, seals, and vibration dampers

Medical Devices

TPU in medical devices

Catheters and medical tubing

Wearable healthcare products

Industrial and Electrical

TPU in cables

Hoses, belts, rollers

Protective sheets and films

TPU vs Other Materials: Material Comparison Guide

TPU vs Silicone

TPU offers better abrasion and wear resistance

Silicone provides higher temperature resistance

TPU is stronger; silicone is softer and more chemically inert

TPU vs PVC

TPU is more flexible and durable

PVC is lower cost but less elastic

TPU performs better in cold environments

TPU vs TPE

TPU provides higher mechanical strength

TPE is softer but less durable

TPU suits for demanding industrial applications

TPU vs Rubber

TPU is recyclable and easier to process

Rubber requires vulcanization

TPU offers superior chemical resistance

TPU vs Nylon

TPU is flexible; nylon is rigid

TPU has better impact resistance

Nylon handles higher continuous temperatures

TPU Manufacturing and Processing Methods

TPU Injection Molding

Used for high-volume production of precision components with consistent quality.

TPU Extrusion

Ideal for producing tubing, hoses, films, and cable jackets.

TPU Sheets and Films

Widely used for protective layers, waterproof membranes, and industrial covers.

TPU 3D Printing

Flexible TPU filaments allow rapid prototyping and customized part production.

TPU Grades and Types

TPU materials are available in various grades to meet specific performance requirements:

Soft TPU – maximum flexibility and comfort

Hard TPU – increased rigidity and load-bearing strength

Flexible TPU – balanced mechanical properties

Transparent TPU – aesthetic and optical uses

Colored TPU – branding and design customization

FAQ’s

What is TPU material?

TPU is a thermoplastic polyurethane elastomer that combines rubber-like flexibility with plastic strength.

Is TPU plastic or rubber?

TPU is a thermoplastic elastomer—it behaves like rubber but processes like plastic.

Is TPU better than silicone?

TPU is better for abrasion resistance and durability, while silicone excels in heat resistance.

Is TPU waterproof?

TPU is water-resistant and commonly used in waterproof films and protective coatings.

What are the disadvantages of TPU?

Higher cost, moderate heat resistance, and precise processing requirements.

Is TPU suitable for medical applications?

Yes, medical-grade TPU is widely used in tubing, catheters, and wearable devices.

Conclusion

TPU material is a high-performance polymer that delivers exceptional flexibility, strength, and durability across a wide range of applications. Its ability to replace rubber, PVC, and other plastics while offering superior performance makes it a preferred choice for manufacturers worldwide.

For businesses seeking a flexible, durable, and chemically resistant material that performs consistently in demanding environments, Thermoplastic Polyurethane provides an excellent balance of performance and process efficiency.